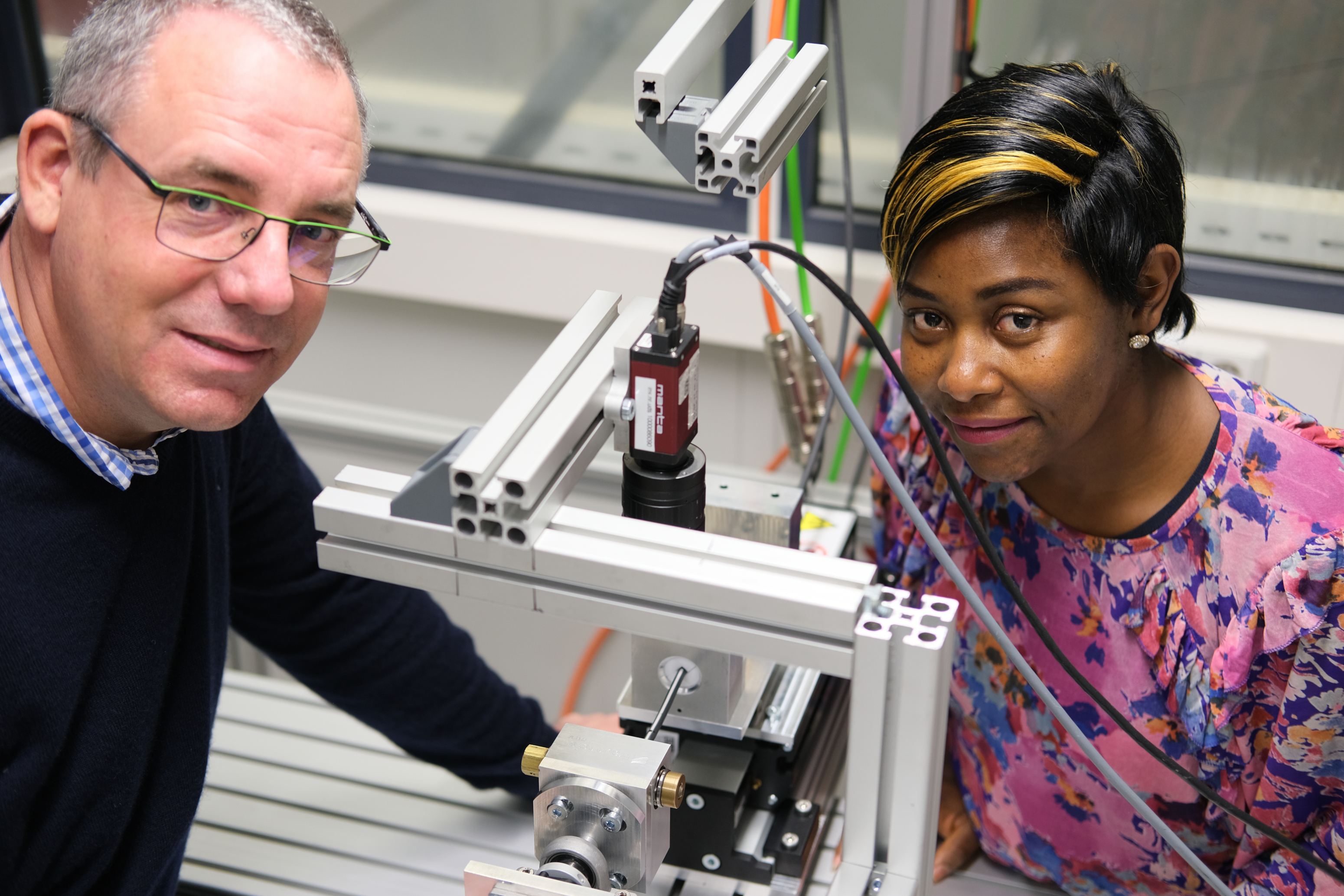

In the project »ProP4CableSim«, our researchers are working on predicting the elastic properties of cable systems. It is part of a special transfer program of the Fraunhofer-Gesellschaft and the German Research Foundation (DFG). Partners of the Fraunhofer ITWM are the Saarland University and the ITWM spin-off fleXstructures GmbH.

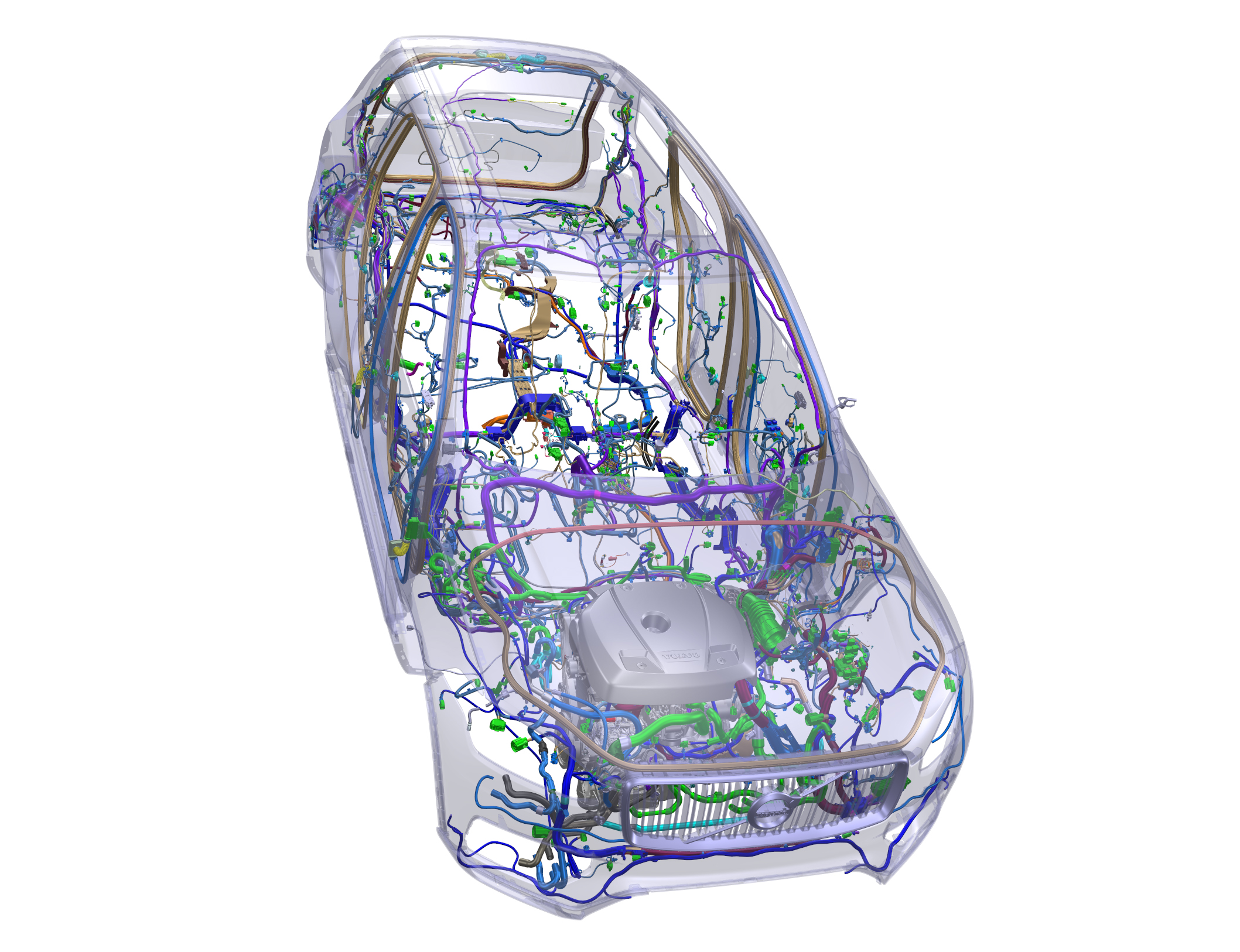

The cable systems installed in modern vehicles are extremely complex. Up to 900 different cable types with different structures as well as functions are used. They supply and link numerous sensors and mini-computers, which communicate with each other and control them in a network: from cruise control, lane or brake assistants, to window regulators.

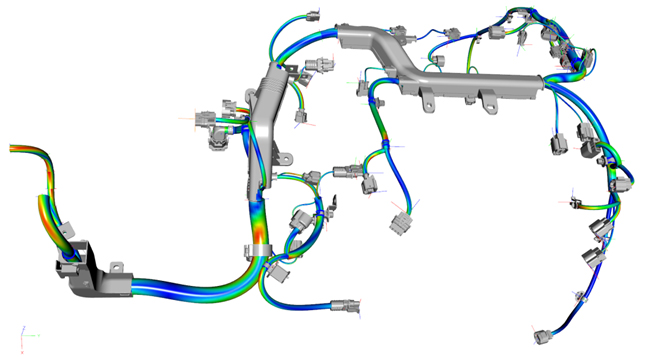

Cable installation is still a complex and time-consuming task. After all, the entire nervous system of the car has to fit into the smallest possible space in the car body and interior trim without any cables getting tangled. Kinking or too much twisting of the cables should be avoided, otherwise soon neither power nor data flow will work. Cables can also get damaged as a result of the complicated installation which leads to safety risks or expensive recalls.

Simulate and Predict Cable Properties

Often, issues in assembly due to too narrow spaces only become apparent in hardware prototypes which makes re-planning necessary. Assembly simulations can be used to avoid this by planning the routing of flexible cable systems virtually in early design phases. Mechanical parameters are required for the simulation models in order to represent the deformations as realistically as possible.