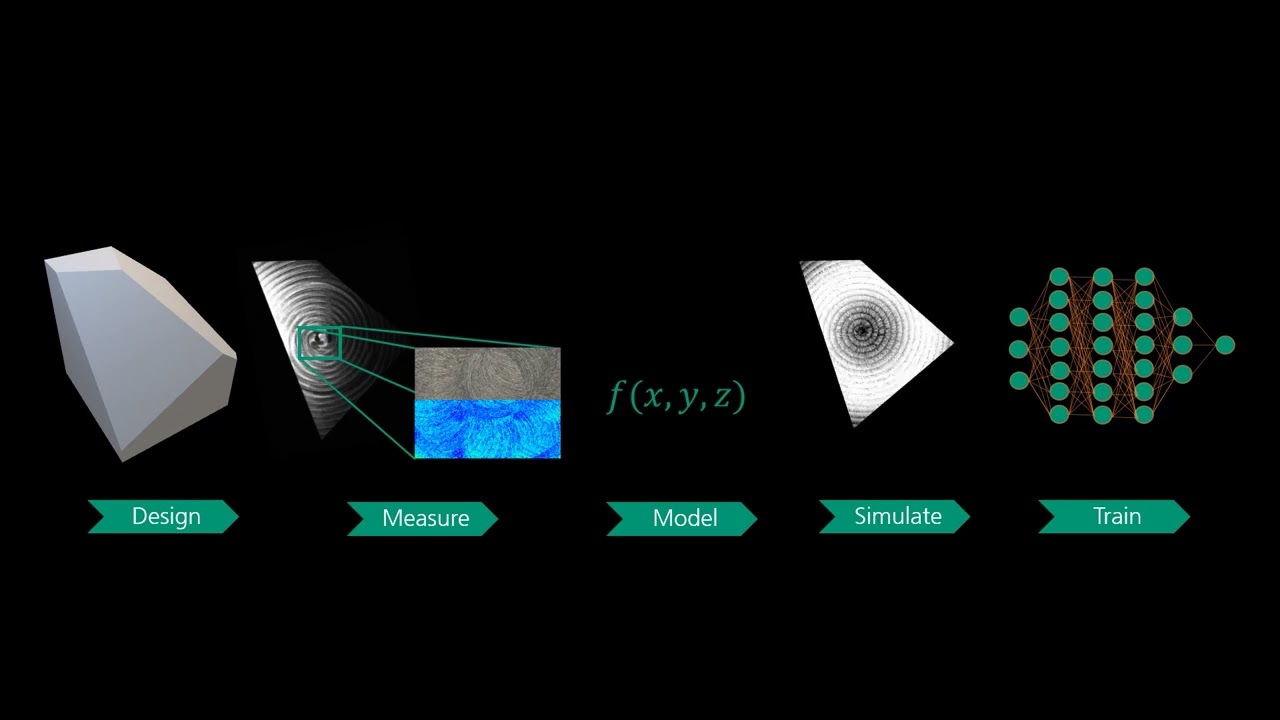

In the project »SynosIs«, we are working with our research partners to develop an inspection system based on artificial intelligence (AI) that detects defects on surfaces quickly and automatically. The project is funded by the German Federal Ministry of Education and Research (BMBF).

Image processing systems for quality control in production are solving increasingly complex tasks and, due to short development cycles, must react ever more quickly to new products and defect patterns. Typical inspection tasks include the detection of surface defects and deviations from the target geometry. Artificial intelligence (AI) is used successfully in image recognition, processing and understanding to some extent. However, training a robust, automatic AI-based inspection system requires a large amount of manually annotated image data, especially one that is representative of all defect types.

Challenges of an AI-Based Inspection System:

- Many defects occur very infrequently. In particular, defects that are critical to component safety are observed less frequently because they are avoided as much as possible on the production side.

- Manual annotation of exemplary defects is therefore not only time-consuming, but also leads to inconsistent results in some cases.

- In particular, the decisions of the trained system may be biased by the lack of defect images in the training.

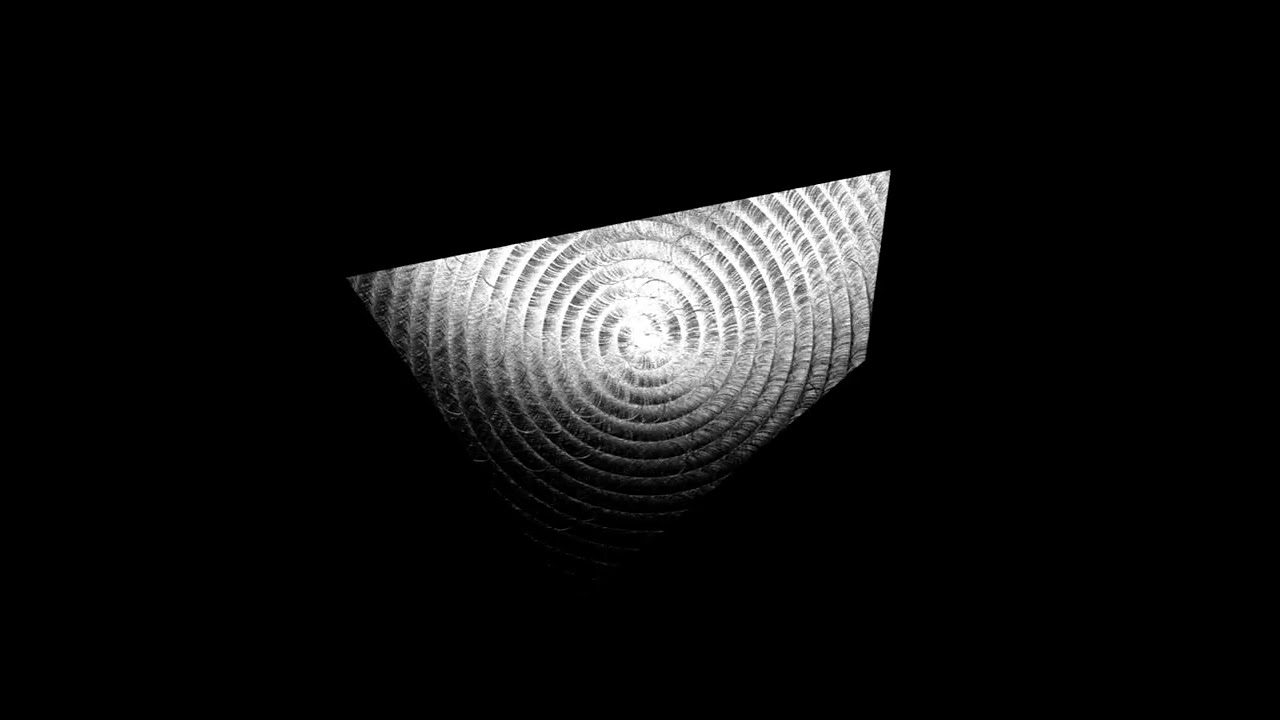

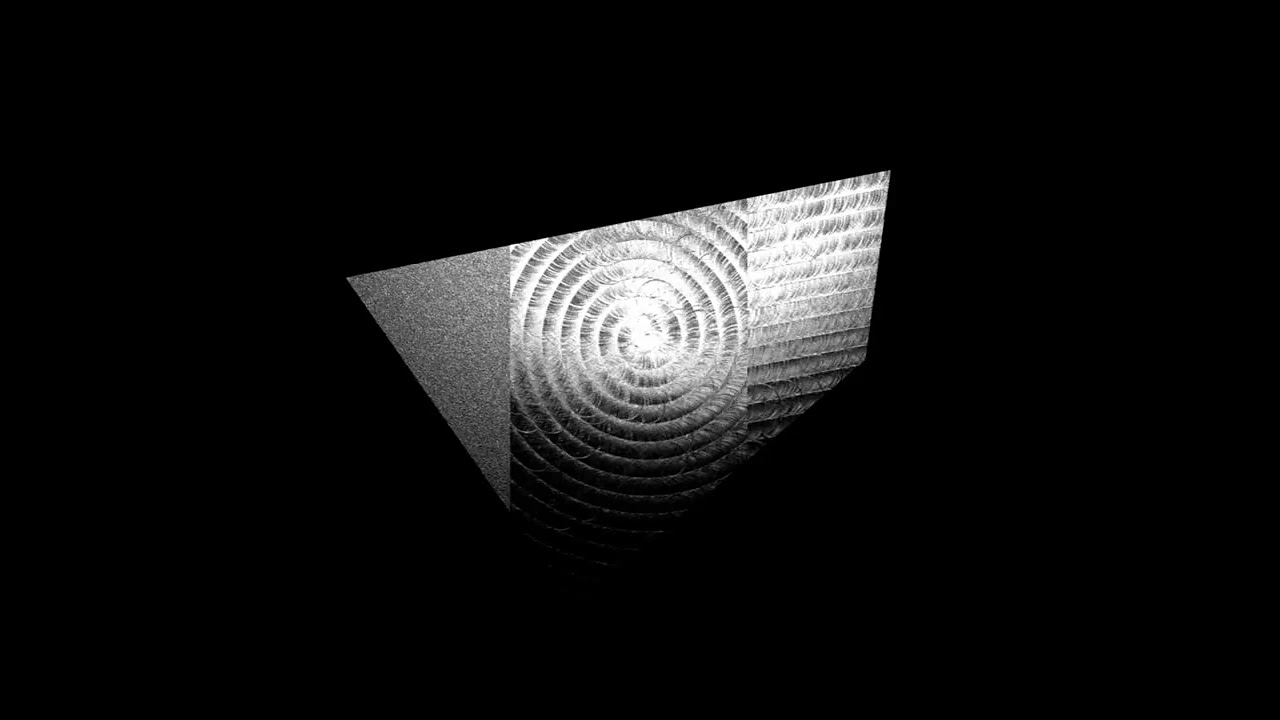

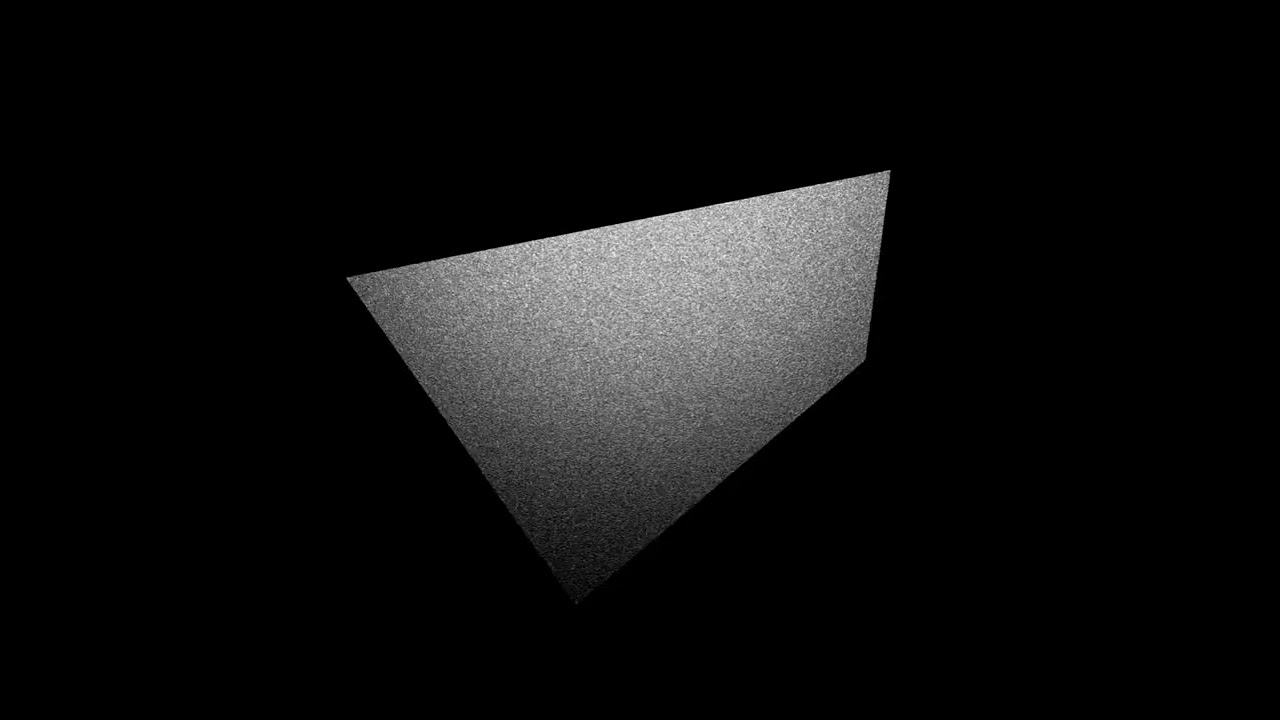

It is therefore desirable to automatically generate realistic synthetic image data together with the corresponding annotations. Currently, the simulation of such image data requires multiple manual interactions. Moreover, synthetic generation of surface defects is an open research topic.