Our statistics program JUROJIN supports the planning and evaluation of durability tests. Methodology and program structure are based on projects and practical application cases with car and commercial vehicle industry. A number of vehicle manufacturers and suppliers are using Jurojin to solve typical tasks quickly and efficiently.

JUROJIN – Statistics for Fatigue Testing and Reliability Analysis

Challenge: Reliability Demonstration is Expensive!

Before components enter production only few and expensive prototypes are available for reliability demonstration. Especially for safety relevant components, this demonstration is crucial.

Several questions arise:

- How many prototypes need to be tested? At what test duration?

- Either many short or few long tests?

- How to analyse the test results?

- Required statistical confidence level?

- Are different suppliers producing the same quality?

- Is it possible to expand a components homologation to a modified version?

- etc.

Solution in Jurojin

Jurojin answers these questions by improving well-tried methods like Maximum Likelihood, depiction in probability papers and Success Runs. Bootstrap algorithms compensate errors from small sizes and utilize all information from censored data.

Statistical package JUROJIN

The implementation of these advanced algorithms has produced the software package JUROJIN. Leading guidelines have been:

- Mathematical benchmark: optimal consideration of all information coming from the sample. Elaborate techniques help lowering the sampling efforts.

- Easy operability: inhibition threshold is lowered by guided handling of tidied up user interfaces. In addition results becomre more traceable.

- Modifiability: professional users define templates for the less experienced users.

Scope of the software package JUROJIN:

- Design of technical survival data and fatigue life experiments

- Data analysis with selected algorithms

- Graphical data reduction

- Consideration of small sample sizes

- Usage of all information coming from censored data

- Calculation of continuative experiments in case of refused homologation

- Analysis of variance

In 2017 and 2018 we made the module "Design of Test Schedules" available for the Android platform, the Microsoft Store and as web app. Next to our extensive desktop suite the most common questions from the catalog above are answered in a lean mobile solution. A free version for smartphones, tablets and Chromebooks can be downloaded at Google Play.

JUROJIN

Adaptive Design of Test Schedules

Adaptive Design of Test Schedules

Classical test designs following the success-run paradigm, need a specific number of parts to reach a given life time without failure. To reduce the number of required components the testing time should exceed the design life by a factor called life time ratio. This leads to an increased risk of not getting the reliability approved, even if the components come from a population with good quality. Testing subsequent components as reaction on that will increase the consumer’s risk. In this case, poor component populations will pass the test with increased probability.

Jurojin quantifies this risk and assists in the selection of a suitable strategy:

- Add few components with the same testing time

- Add more components with decreased testing time

- Reactivate some of the components without failure

Efficient Woehler models

Efficient Woehler Models

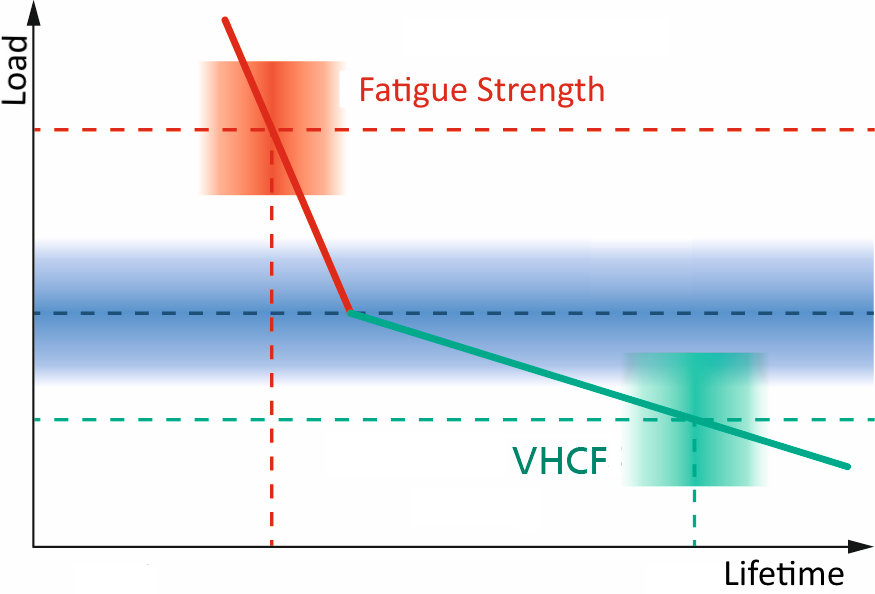

For cyclic loads with medium to high amplitudes, the relationship between load amplitude and fatigue strength (S-N-curve) is often observed to be linear in a double-logarithmic diagram. For lower amplitudes, a nearly horizontal curve is typical. In this range loads may theoretically be applied “infinitely often” (more than 10**6 repetitions). Traditionally, regression in load direction is performed based on the information [component fails/component is durable] to identify the endurance strength.

The fact that fatigue and endurance strength are evaluated separately leads to information loss. Driven by industrial cooperation projects we developed a new stochastic model that allows joint identification of high-cycle fatigue and infinite life or very-high-cycle fatigue behavior. Random variables describe the transition region and the scattering of the fatigue life.

Reliable warranty data evaluation

Reliable Warranty Data Evaluation

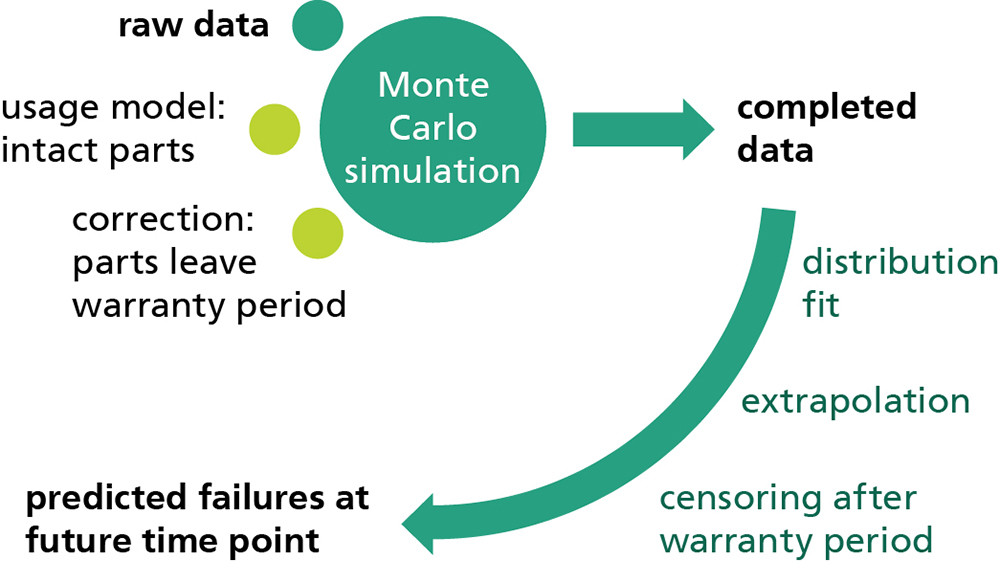

In addition to evaluating components under development, JUROJIN also supports the analysis of warranty data for parts already in production. The available input data for such an analysis only refers to failed components and provides no information on the fatigue life of intact components. Forecasting on this basis typically would be too pessimistic. Also, as soon as the first components are no longer covered by the warranty period, defects are no longer fully reported to the manufacturer. In this situation, the forecasts would become too optimistic.

In projects with industrial partners this incompleteness (missing data) has been modelled and a corrected likelihood-function developed. Combined with a usage model of the intact units, JUROJIN now applies Monte-Carlo simulation to calculate statistically complete data as a basis for extrapolation. Reliable failure forecasts for future time points are thus possible even in the early phases of the warranty period.