Coatings often not only enhance aesthetics, but also have functional properties; these include protection against mechanical influences and harmful weather influences or the improvement of the haptics. Coating thickness is therefore of particular importance in industry.

Coating Thickness of Enameled Wire

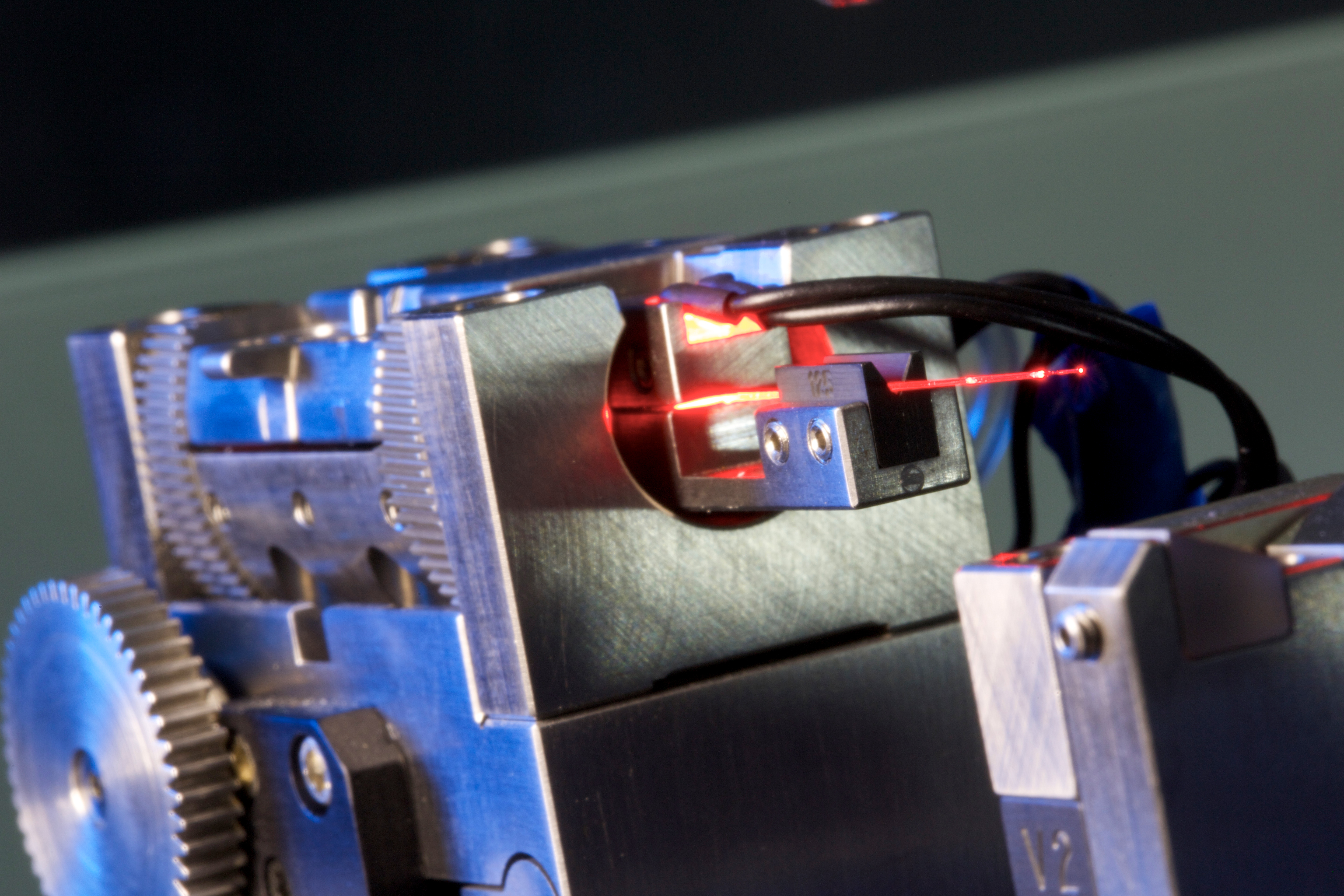

Functional properties require a minimum thickness, unnecessary thick layers waste resources and thus increase production costs. There is now a solution for measuring very thin, semitransparent layers: optical coherence tomography (OCT). This method has been originally developed for the depth-resolved visualization of biological and medical materials. Thanks to intensive research, it has now also established itself outside medicine. High-resolution sample cross-sections, which are generated completely non-destructively in real time with visible or infrared light, make the OCT the ideal non-contact inspection technology for many applications.

Reflection provides information

The physical principle behind this method is the interferometric superposition of a light beam, which is reflected from different sample depths, with a reference beam. From the intensity and temporal shift of the reflected beam, the depth information of the sample can be determined mathematically and displayed as a cross-sectional image. The resolution is between 1 and 20 μm, depending on the spectral width. Optical coherence tomography is suitable for all materials that are at least partially transparent to visible or near-infrared light. These are many plastics, composite materials, glasses, ceramics or semiconductor materials.

Inspection of enamelled wire

Enamelled wire, also known as winding wire, is a metal wire coated with an electrically insulating enamel layer during production. The thickness and weight of this lacquer insulation is very low compared to other insulating materials with the same effect. This wire is therefore preferred for the construction of electrical coils, transformers and machines. We successfully use OCT to measure the enamel thickness on copper wires. The thinnest wire had a diameter of 25 µm and a coating thickness of 3 µm.