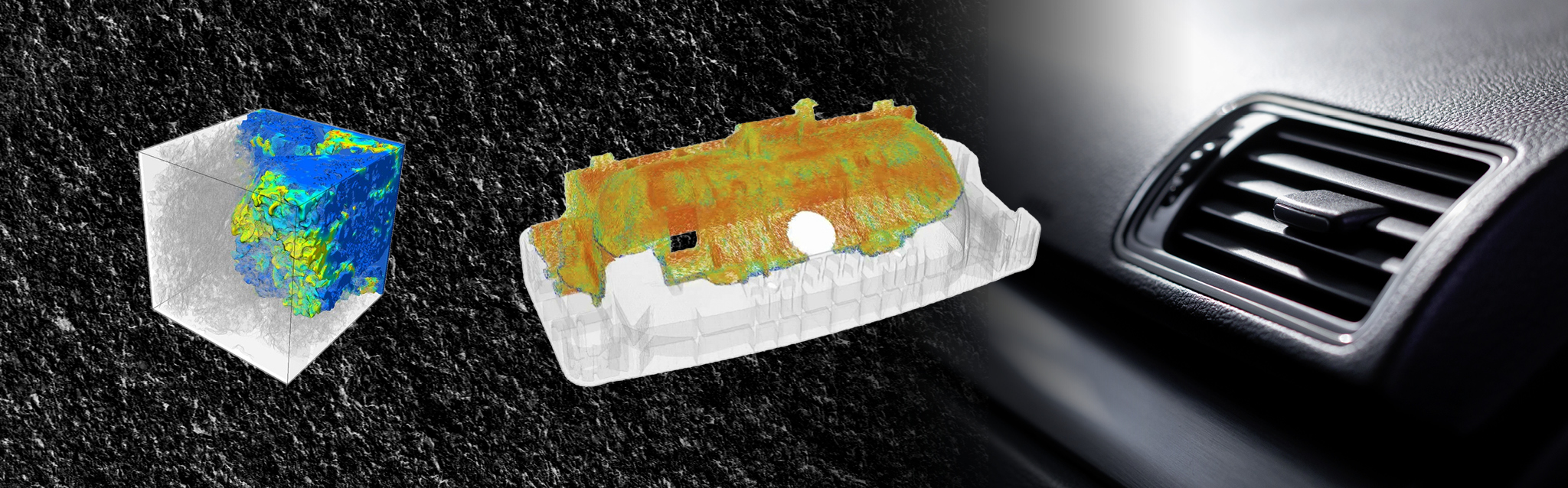

FLUID is our extremely robust flow solver that correctly calculates especially complex rheologies (deformation and flow behaviour of substances) of multiphase flows (miscible and immiscible) in and around porous media. Thus, the software is used to simulate and optimise manufacturing and processing processes of polymers, particle and fibre suspensions, foams, concrete and much more.

To be able to provide simulation solutions for such a wide range of materials and physical effects, we have developed FLUID to ensure the rapid implementation of new rheological models and their robust and efficient solution of any multi-physics systems for industrial applications.