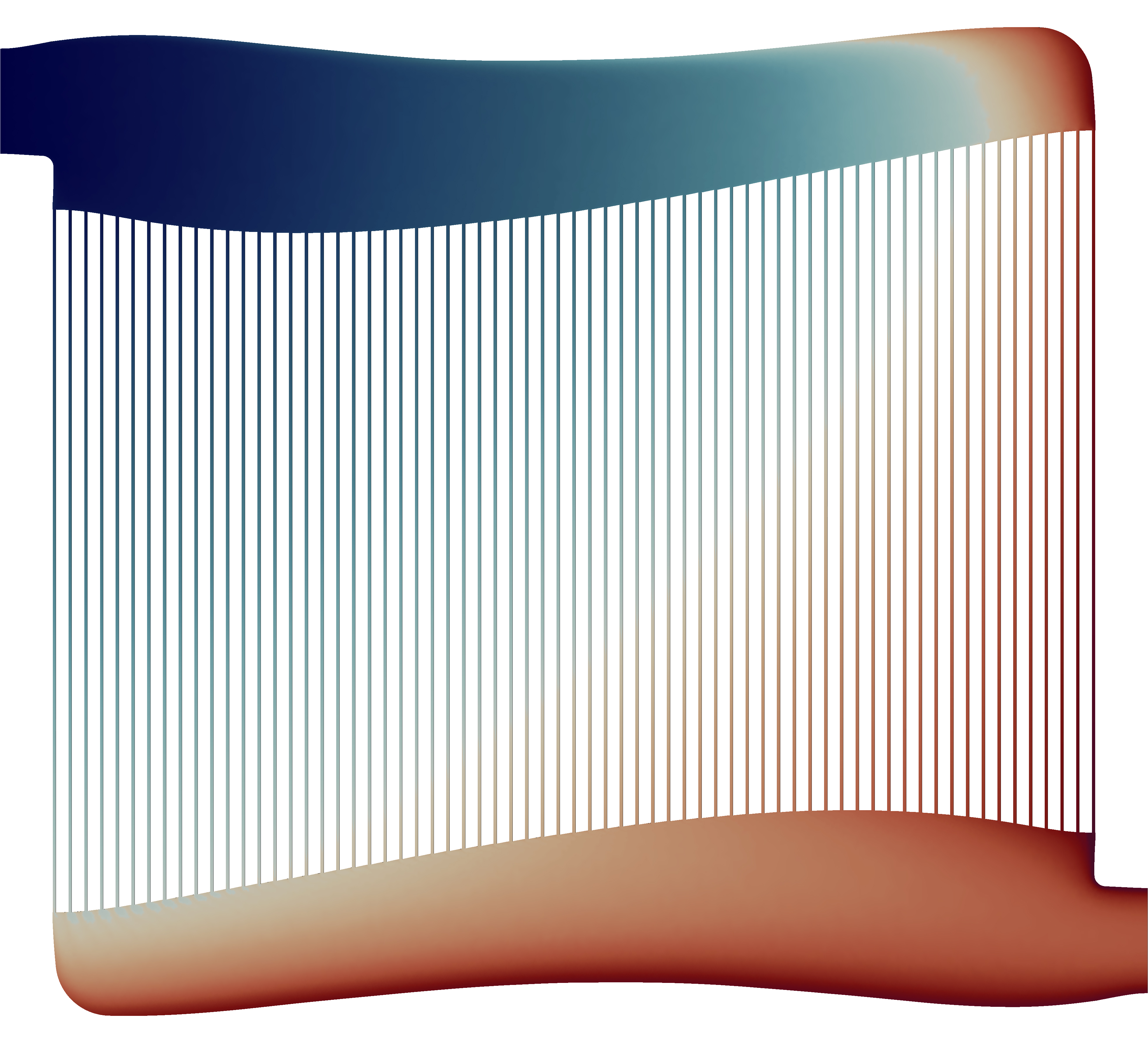

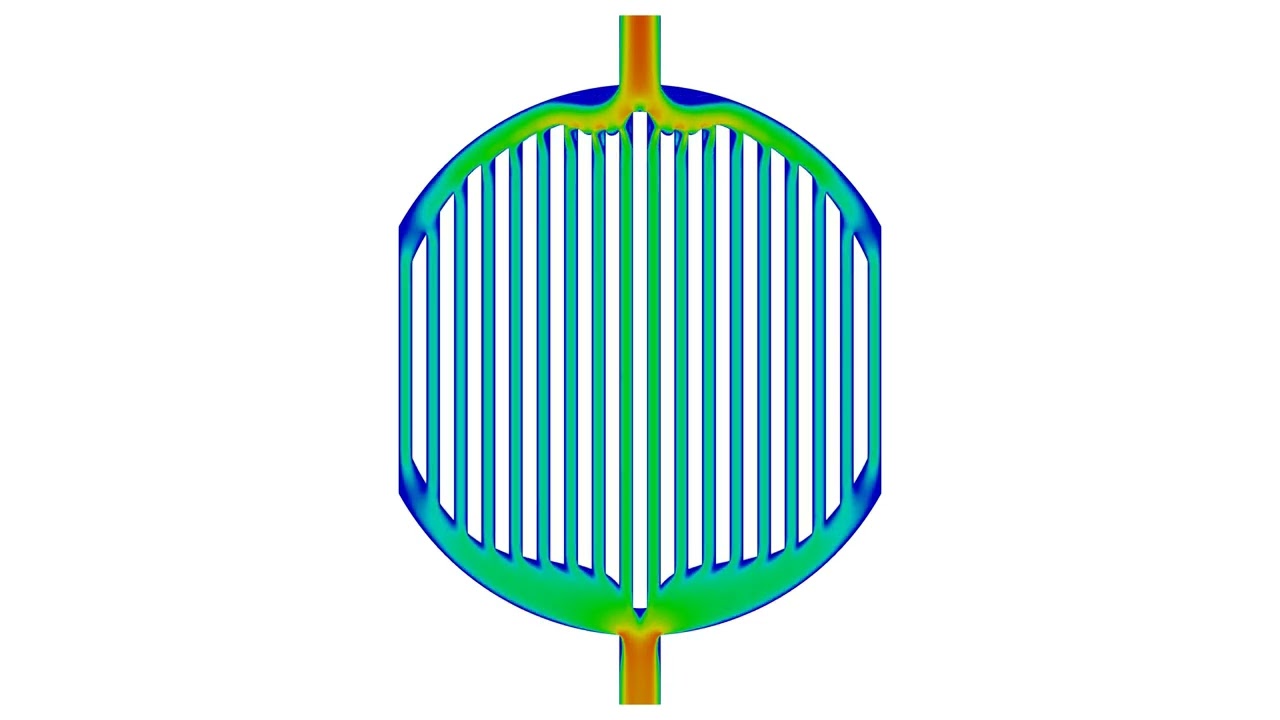

Our sophisticated software package cashocs supports the solution of industrial problems by solving shape optimization problems and providing new design suggestions. As a special focus, we use cashocs in fluid dynamics, where we use the software to improve flow components, e.g., in continuous chemical reactors.

Fluid dynamic shape optimization deals with the question of how an improvement of a flow component – e.g. continuous chemical reactors or electrolysis cells – can be achieved. How should the shape of such a component be modified in order to improve the process? This is often crucial as special process conditions, such as a uniform flow or residence time distribution or a low pressure loss, must often be achieved in the components. Our software cashocs automates the shape optimization of such components and systems for industrially relevant problems. This enables us to solve even extremely complex problems within the shortest development time.