Enhanced Color Perception: From Red, Green, Blue to Hundreds of Color Channels

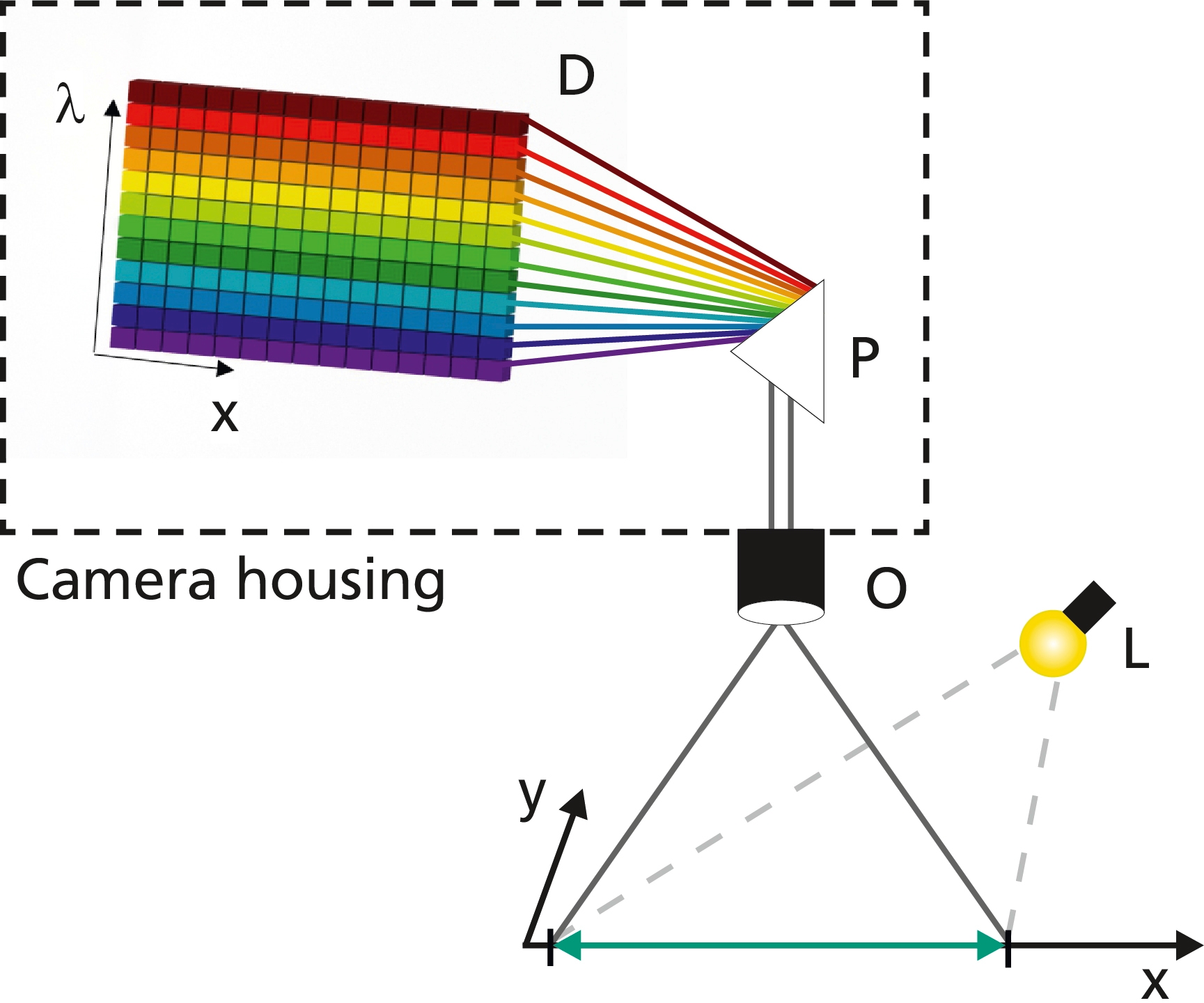

Hyperspectral imaging is revolutionizing the way we perceive color and light. Normal cameras capture images in three colors - red, green and blue. This limitation is sufficient for many applications, but hyperspectral cameras go far beyond this. They use several hundred color channels and thus enable extended color perception. This is particularly useful for scientific and industrial applications where accurate spectral information is required.

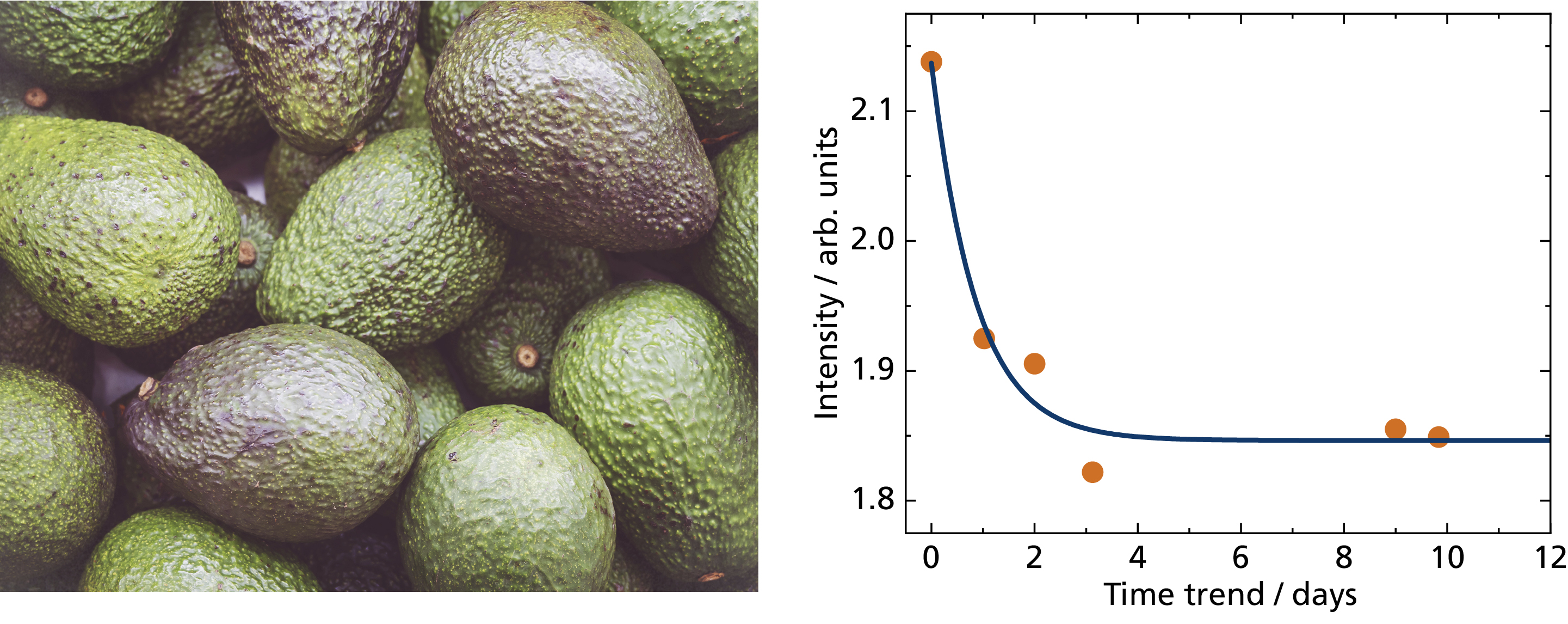

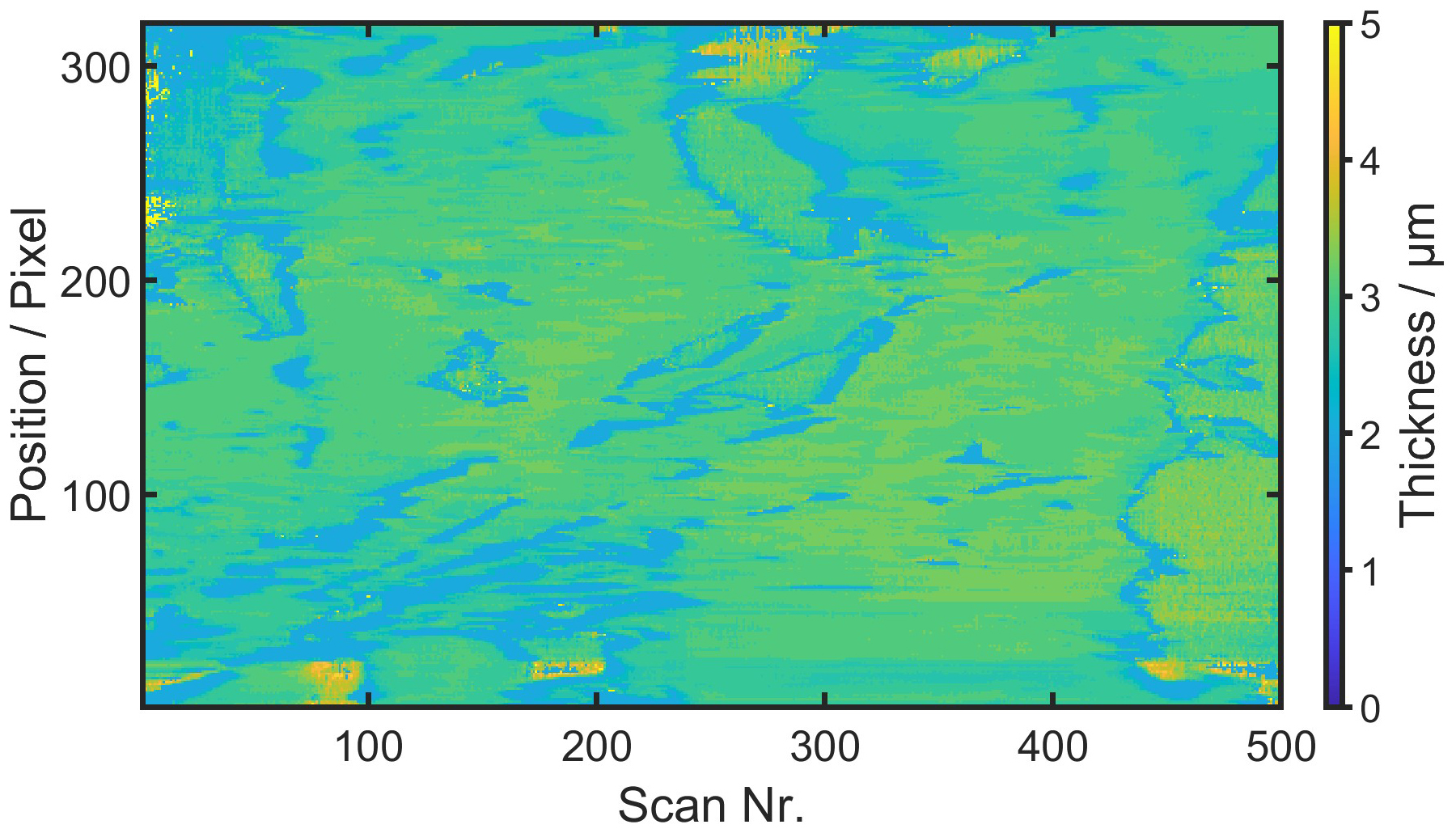

Thanks to the many color channels, hyperspectral cameras can precisely capture the spectral properties of samples. This means that we can use them to detect differences in materials and substances that remain invisible to the human eye or conventional cameras. This technology is used, for example, in materials testing, agriculture, environmental monitoring and many other areas.

We use hyperspectral cameras for visible light and near-infrared (non-visible) light. This expands the application, as the near-infrared spectrum provides information that is not available in the visible range. This makes it possible, for example, to visualize the water content in plants or certain chemical compositions in materials.