FPM can be used excellently for applications in glass industry because of frequently occurring problems with free surfaces, e.g., during the casting process of glass into molds or the transport of molten glass in open channels. Additionally, there are problems of moving geometry with respect to time.

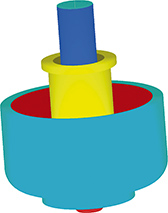

Simulation of Filling a Hollow Cylinder

For the company Schott Glas, the Fraunhofer ITWM has simulated the simple filling of a hollow cylinder with an extremely short glass. Such a glass is characterized by a strongly increasing viscosity of the material if the glass temperature decreases, the increase showing an exponential character. In order to fill the cylinder, a pipe is inserted between the external and internal wall of the cylinder, moving upwards during the filling process according to the upward movement of the free surface. One of the interesting technical problems now is which filling temperature must be selected in order to guarantee a sound filling of the cylinder without a solidification process starting too early.