In this field of activity, we present various projects from the following topics:

Simulations in Lightweight Construction and Insulation Materials

Modelling, Simulation and Optimization in Lightweight Construction

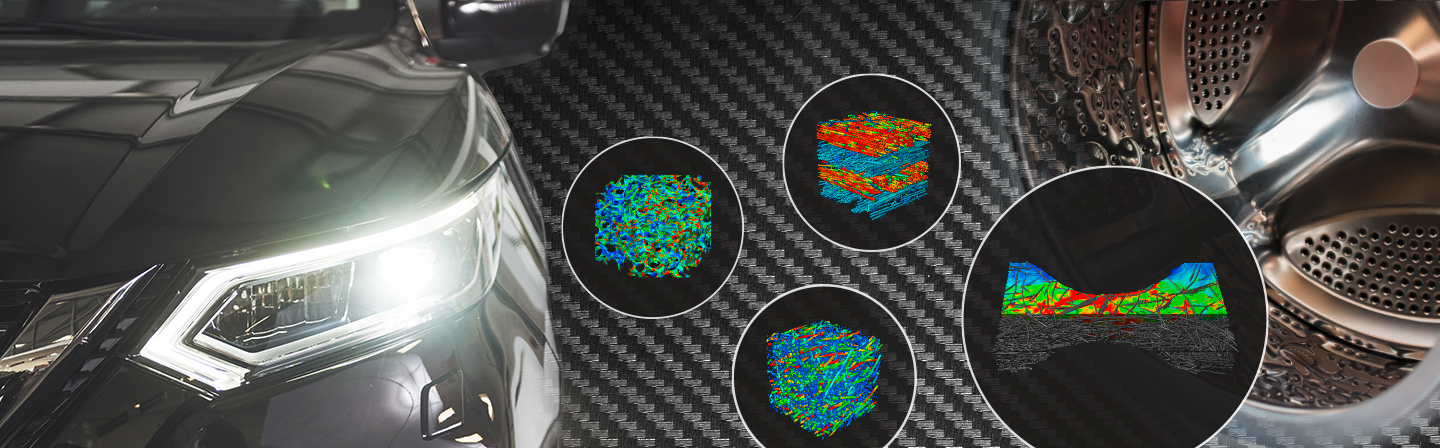

Lightweight construction is already used in a variety of ways today. In the automotive industry as well as in the construction, leisure and sports industries (e.g. sports shoe soles) and in the consumer sector (e.g. drill housings), fiber- and particle-reinforced plastics are increasingly replacing metals as materials. As both the materials and the design, joining and manufacturing processes are continuously being innovated and developed, goods with the same or even improved properties compared to the original product are created.

The prediction of the strength and damage behaviour of these components is complicated due to the directional dependence of the mechanical material behaviour, which is why elaborate multi-scale simulations are necessary for precise predictions. In order to reduce the high computational times, we develop model reduction methods that determine the effective material behavior, such as fatigue and damage, using microstructure simulations with FeelMath.

Modelling, Simulation and Optimization of Insulating Materials

Thermal or acoustic insulation materials are usually highly porous fibre or foam structures, which on the one hand should have the lowest possible thermal conductivity or high acoustic absorption, but on the other hand must also be permanently stable. The optimal selection of the material structure thus requires the determination of the different material properties and the quantitative evaluation of the conflicting criteria.

Based on microstructure simulations with GeoDict, we improve the fiber and foam structures with respect to their properties. In a second step, we can also optimize the design of multilayer systems. For the latter we also use measured input data.