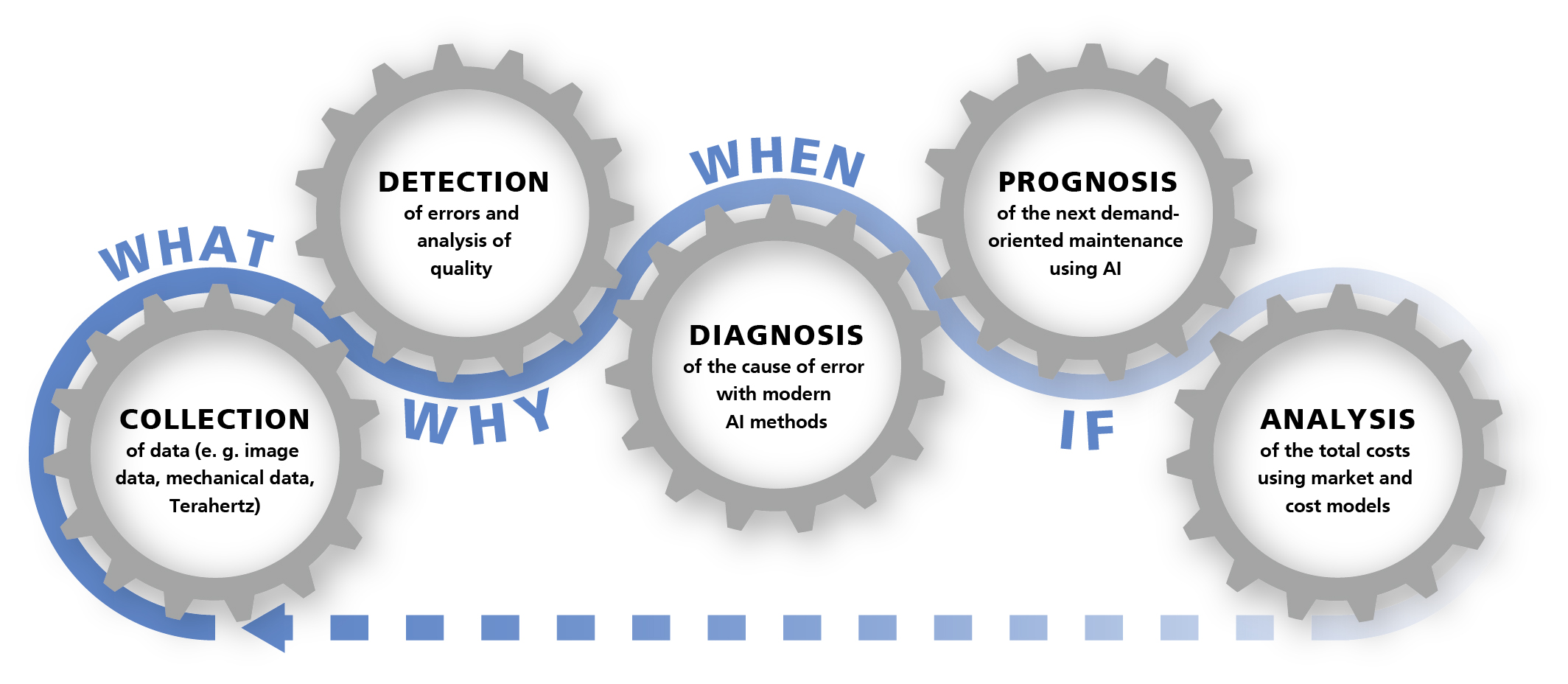

Our Competences and Services

We support you in the development of modules to optimize the effectiveness of your systems and quality analysis of your products from a single source, step by step throughout the entire product lifecycle. Or we can supply you with the appropriate modules. Our services are modular in structure:

Module Data Acquisition, Data Transfer and Quality Analysis

- We analyze existing and determine required information/measurement data for your applications, e.g. for quality analysis or creation of a digital twin. In doing so, we use existing sensor technology or, if required, we are happy to offer the special systems developed by us:

- Innovative image-based complete solutions for automated quality analysis (e.g. surface inspection)

- Terahertz technology for coating thickness measurements

- Torsion detection by means of contactless torque sensors

- We support you in data transfer from the sensor to the analysis unit.

Condition Monitoring Module

We identify, develop and integrate customized machine learning or deep learning algorithms for your data and information system for condition analysis and diagnosis. Examples are our online monitoring systems for torsional vibrations of rotating plants.

Predictive Maintenance Module

We prepare forecasts for the demand-oriented planning of service and maintenance actions, also based on information from plant parks. Together with you, we design solution-oriented predictive maintenance algorithms for your individual plant.

Module Cost Models

We create and consider market and cost models for the maintenance of your machines and plants for the total cost evaluation of the maintenance measure. In particular, we consider energy prices, which we calculate with innovative models based on financial mathematical methods. Special attention is paid to flexibilities that allow you to profit optimally from fluctuating energy prices.

Our solutions can be integrated into common IOT platforms. We also support you in the development of your individual solution.