Large battery factories are being built in many places in Europe to meet the demand for cells. As this production is very space-, energy- and time-intensive, it is important to design the production processes as efficiently as possible without negatively affecting the product properties of the battery cells. We provide support here with physical simulation models for specific process steps.

Simulations for Battery and Cell Production

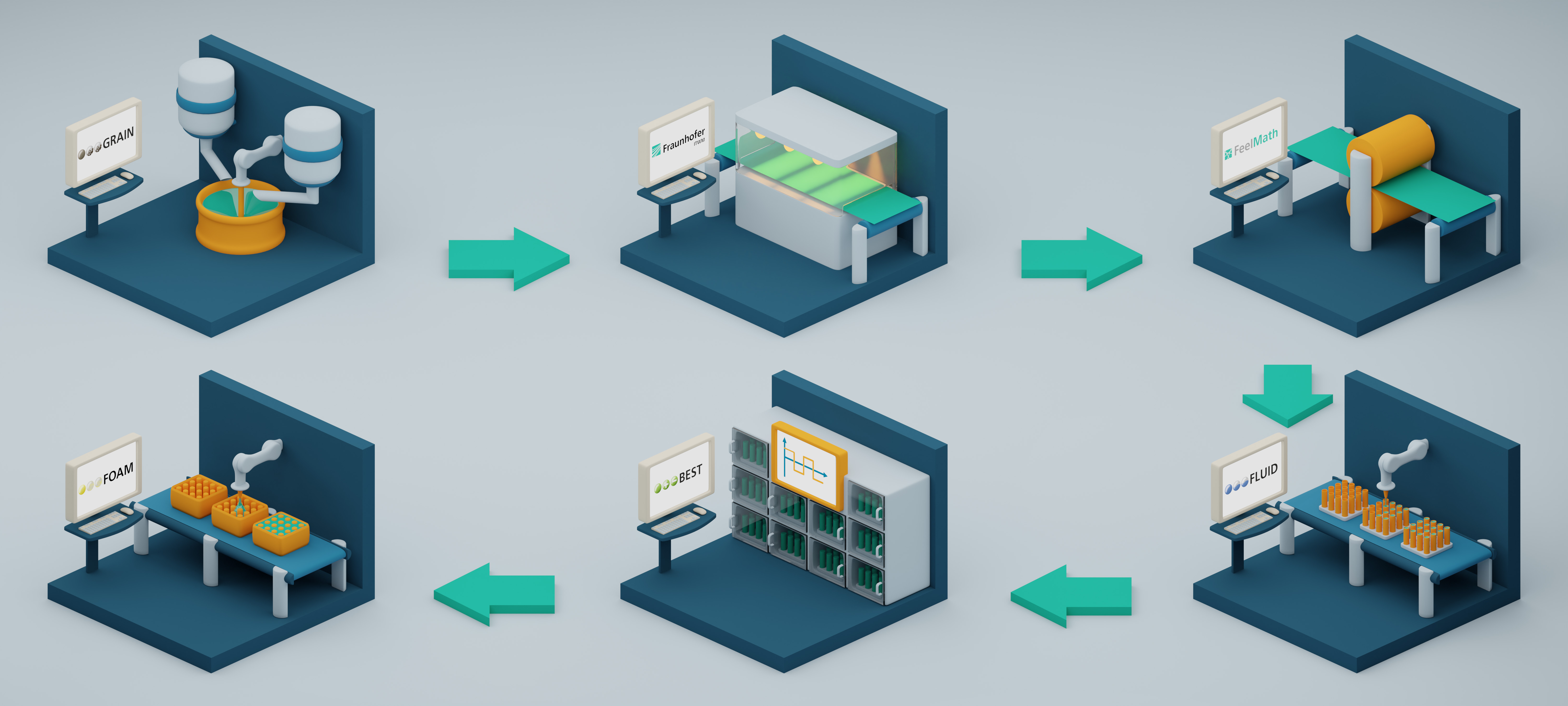

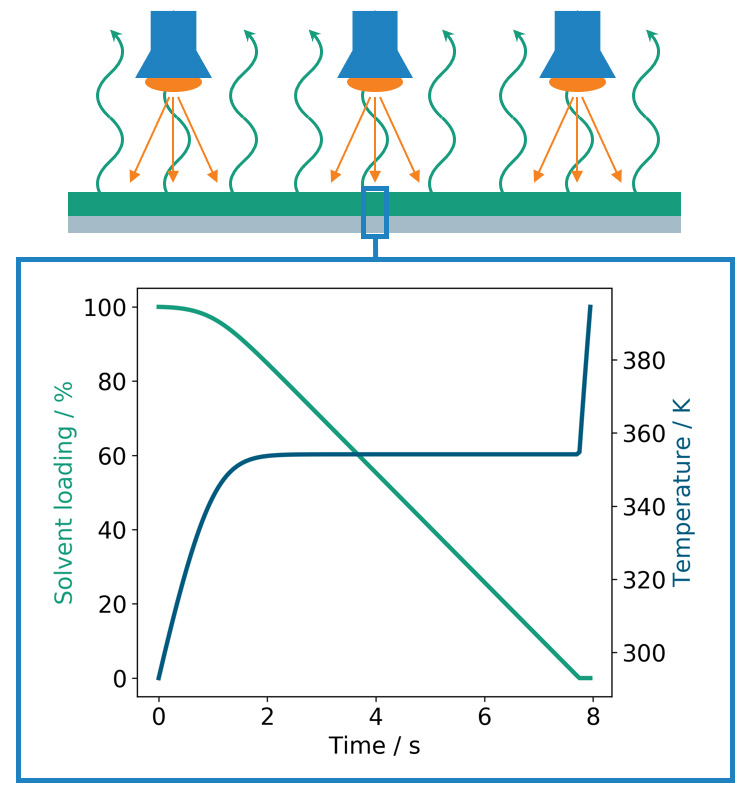

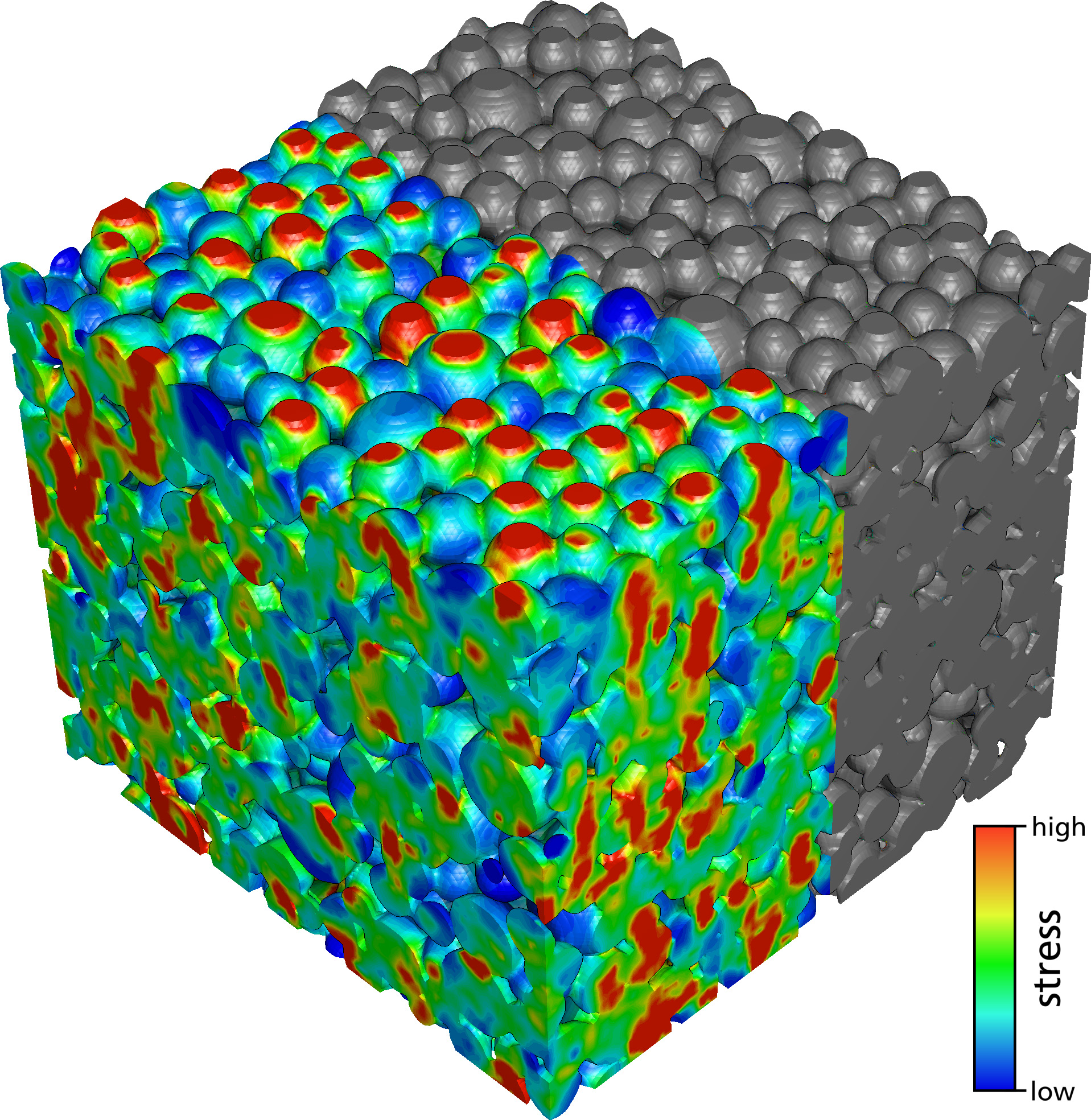

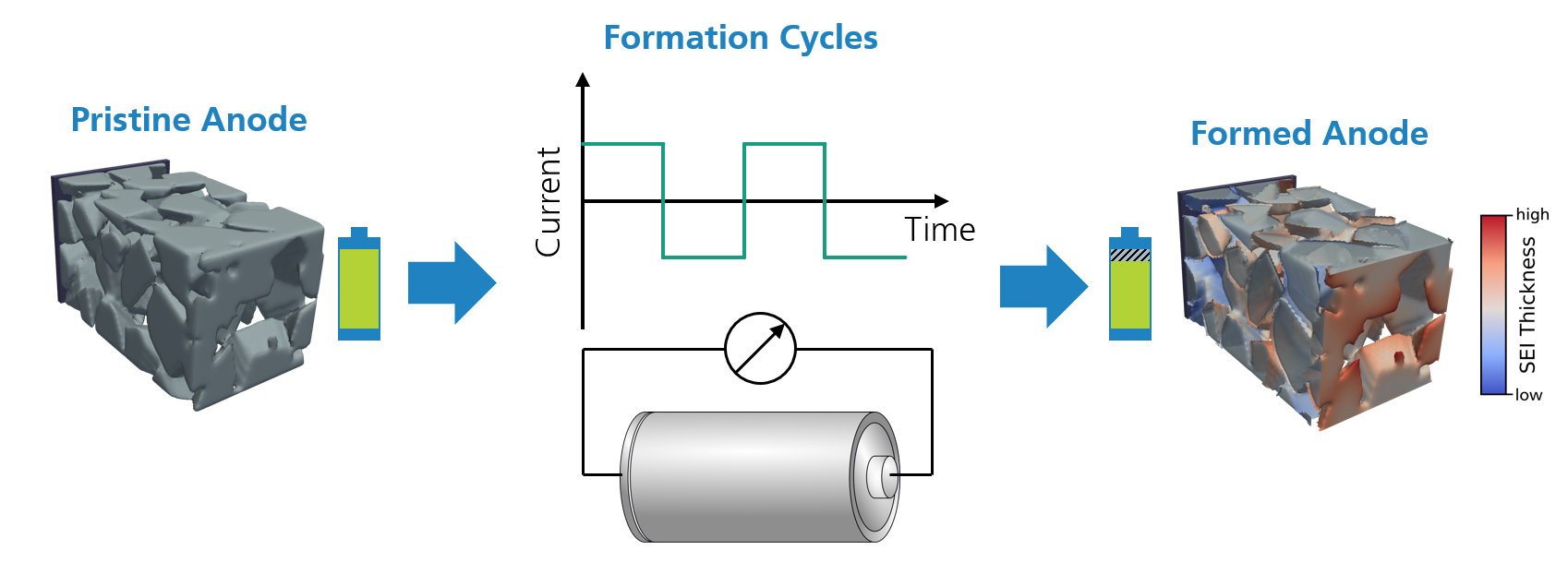

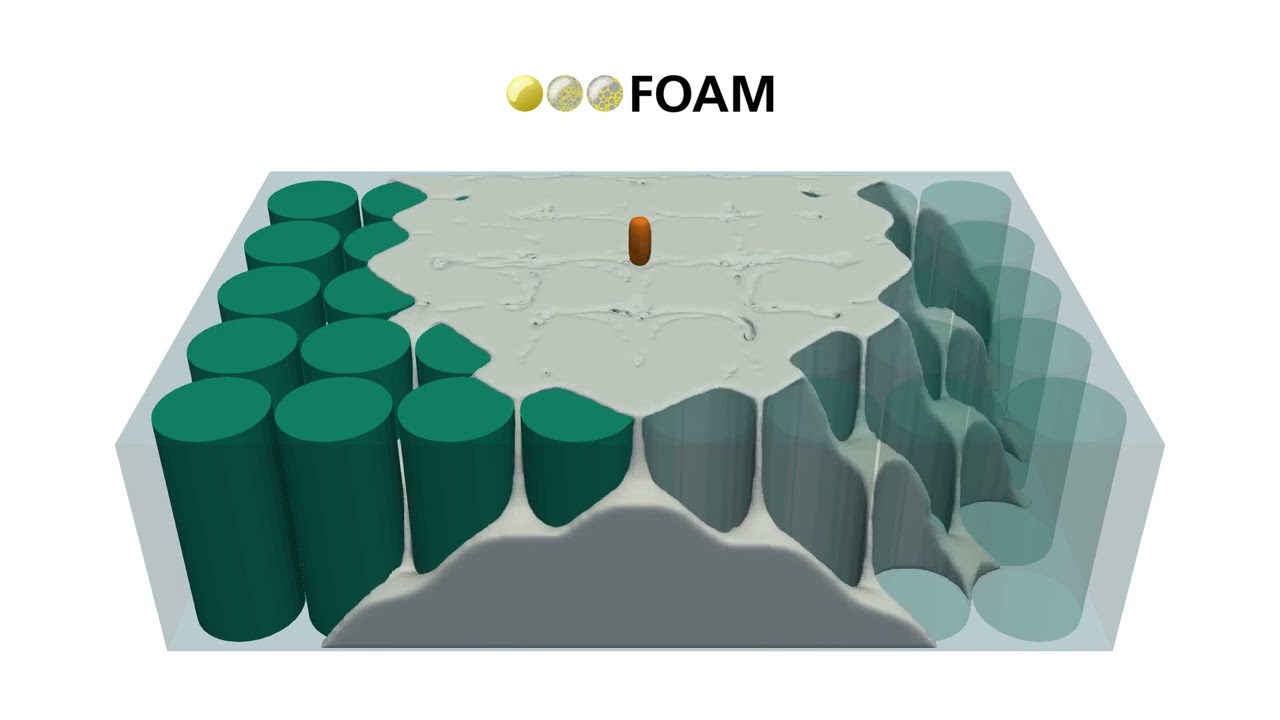

The production of cells and batteries is a chain of many complex individual processes. The main cell production processes can be divided into electrode production (mixing, coating, drying, calendering) and subsequent cell assembly (separating, stacking/wrapping, packaging, electrolyte filling, forming). Depending on the cell format (pouch, cylindrical, prismatic), the finished cells are then typically assembled into modules (this includes electrical contacting, thermal insulation, mechanical bracing). Several modules are then combined into a pack. While the assembly of the battery pack is mainly mechanical or electrical in nature, complex physical processes are involved in cell production.

Describing these production processes using simulations requires the adaptation and expansion of simulation techniques and has only been carried out for a few years in funded research clusters (e.g. Project »Cell-Fi« – electrolyte filling of battery cells)and EU projects (e.g. project »DEFACTO« – New methods in the development and production of battery cells)also developed with the participation of our institute. Our department »Flow and Material Simulation« has gathered know-how in many key areas of industry applications, which now provides a strong foundation for analysing and optimizing cell production.