Fiber reinforced plastics have a high stiffness to weight ratio and can be cost efficiently produced on a mass production scale by injection of compression molding. Therefore, this type of material plays an important role for producing lightweight components. In joint projects with Bosch, we developed an integrative simulation for the dimensioning of short fiber reinforced components, which takes into account the production process as well as the resulting locally varying material properties.

Our Solutions in the Entire Production Process

During the production process the plastic is injected or molded at medium to high pressure into the component shape. The resulting flow processes are influencing the fiber orientation and thus the mechanical properties significantly. At first, a material database for different fiber orientations is filled during the so called off-line phase. This stage is relying on a combination of microstructure simulations performed with FeelMath and model order reduction methods.

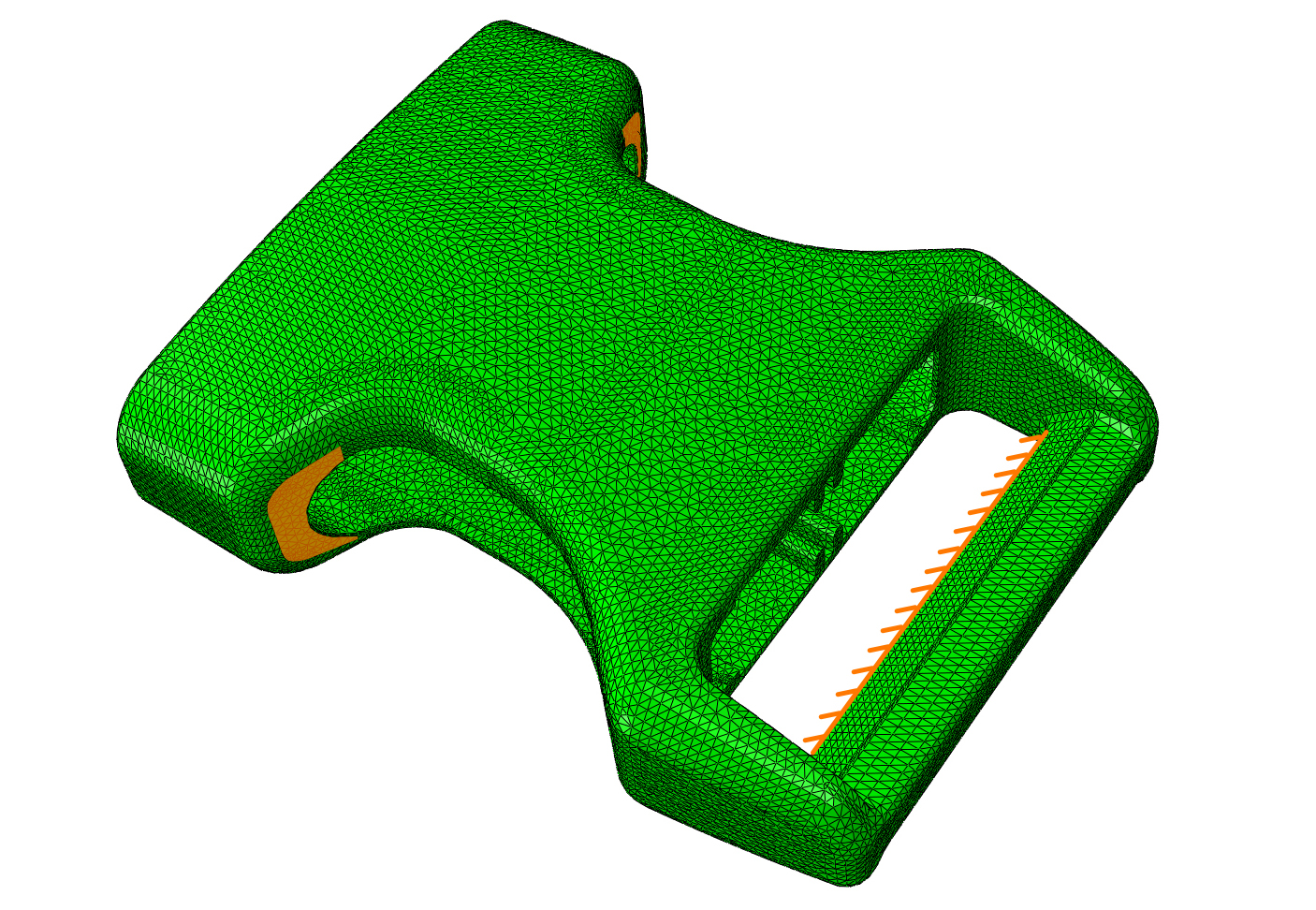

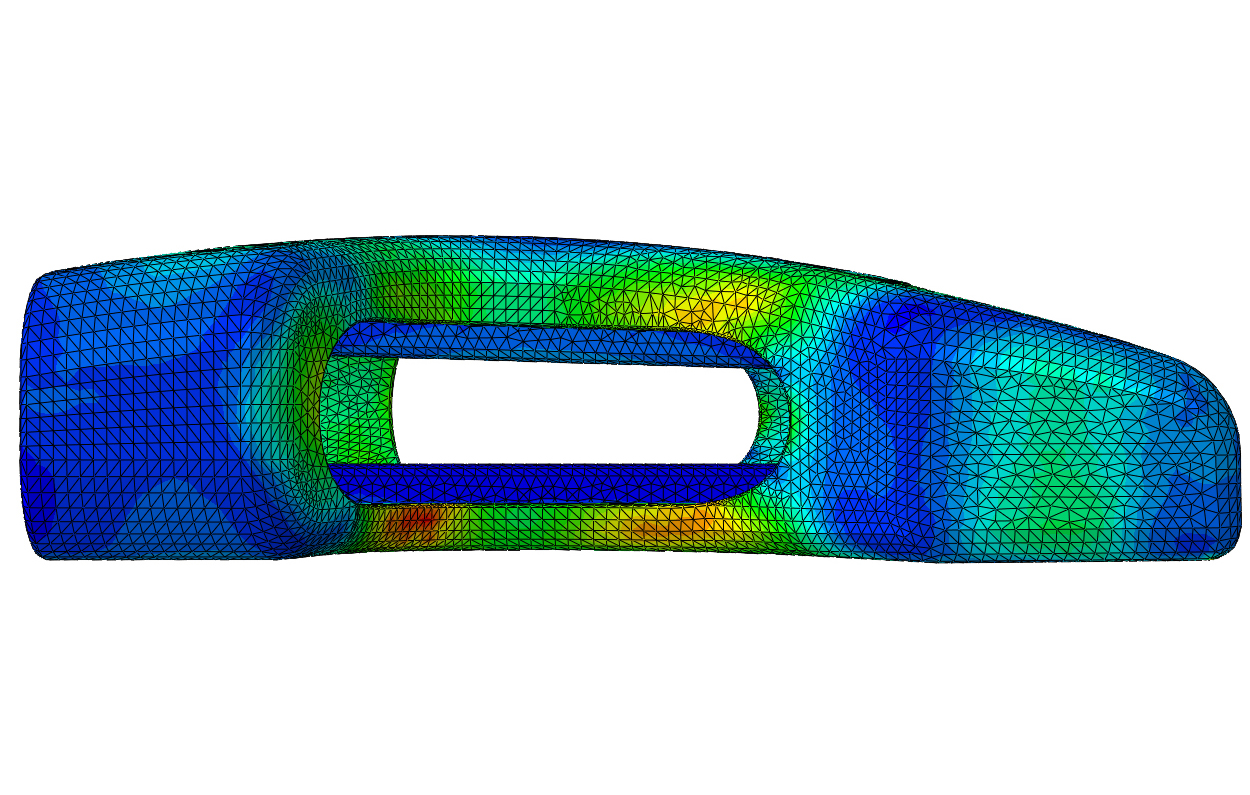

FeelMath is a fast and easy analysis tool for elastic micro-structures given by volume images (e.g. CT-Images) or analytical descriptions. Afterwards, the results of the injection simulation with FLUID, Moldflow or Moldex 3D are transfered onto the Finite Element Mesh (FE-Mesh) of the component simulation.

During the component simulation with Abaqus we are interpolating depending on the actual fiber orientation between the effective material laws obtained during the off-line phase and take account oft he local nonuniform mechanical properties. This allows us to take advantage of the lightweight capabilities of fiber reinforced plastics and to avoid overly large safety factors.