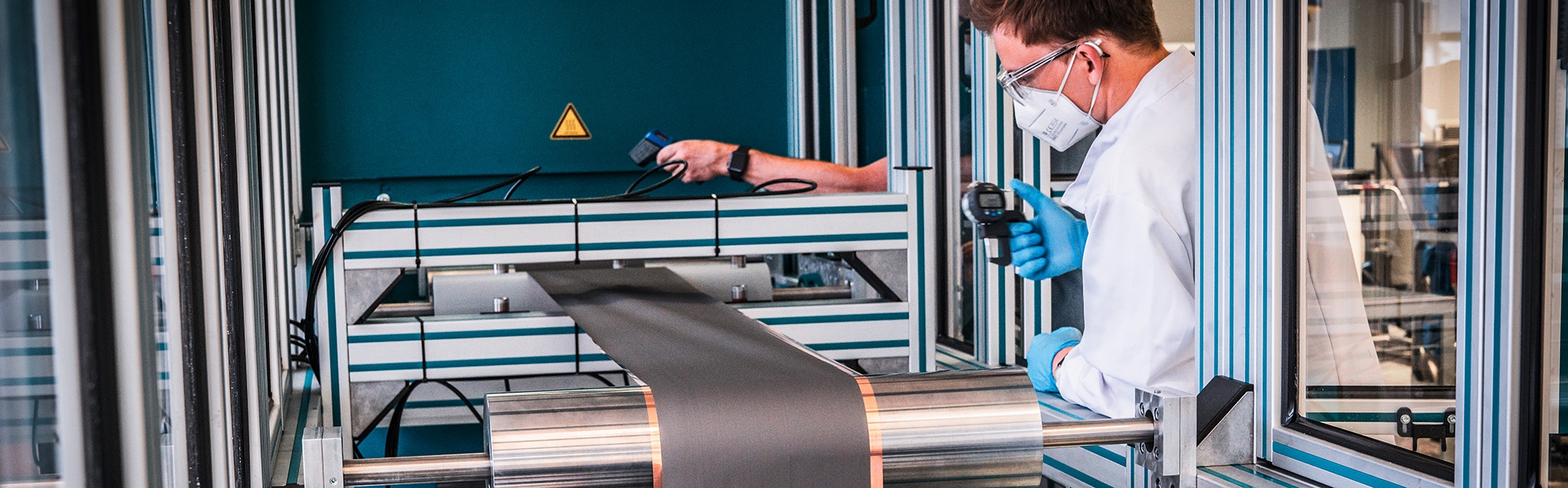

Battery foils are the main components in lithium-ion battery cells. The continuous monitoring of material parameters – layer thickness and conductivity – is crucial for product quality. We use our terahertz measurement technology to monitor them inline during production. The measurements are carried out inline on single- and multi-layer coatings at various points in the wet or dry process – always contact-free and non-destructive. Quality control during the manufacturing process quickly pays off.

Lithium batteries – used in electric vehicles and large battery storage systems – consist of anode and cathode foils that must have different properties depending on their function. Measuring these properties, in particular the conductivity and layer thickness, is essential in the development and production of efficient batteries in terms of energy density and longevity.