Electronic components in vehicles, like control units, are affected by various different loadings, e.g. due to:

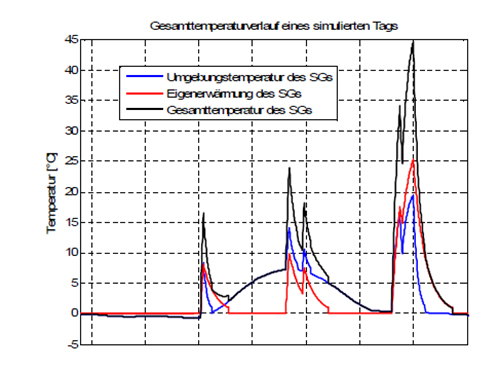

- temperature changes

- long stay at high temperature

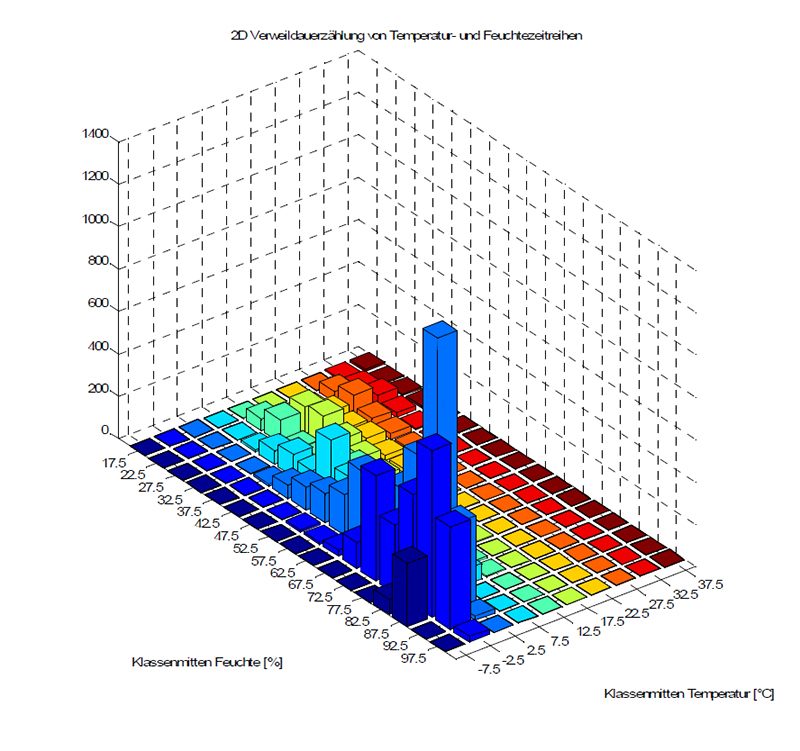

- simultaneous influence of temperature and humidity

The time series of temperature and humidity for a whole vehicle life depend on many influencing factors, like climate, vehicle usage or vehicle dependent mounting location.

Knowledge of realistic temperature and humidity time series is necessary to determine resulting damages of a whole population of control units in customer usage. Collecting real-world measurements is due to the variety of influential factors and the need for long test periods to cover climatic changes a very demanding process.