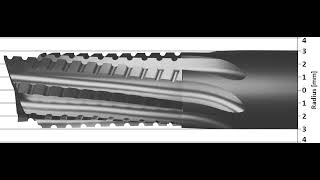

Development of coated cutting tools is a highly specialized and expensive process. Coating enhances the tool’s cutting performance and extends its lifetime. When the coating is not applied correctly, the tool will malfunction and potentially cause further damage to the object it was cutting. However, the coating defects are measured in micrometers and are close to impossible to collect in a catalogue. How can automate the inspection process? This is where the rule-based synthetic data comes into play. In the »SimVision« project, researchers from the Fraunhofer Institutes ITWM, IGD and IST work together with TU Wien to develop scalable pipeline for training Artificial Intelligence with synthetic data.

»SimVision« stands for »Simulation-Based Visual Inspection«. A central component is the creation of a synthetic data set for Machine Learning with synthetic image data that is realistic enough to prepare AI models for practical use. But how realistic does this data need to be? How does the data influence inspection accuracy? And how can we model defects which we have never seen? These questions are at the heart of the research.