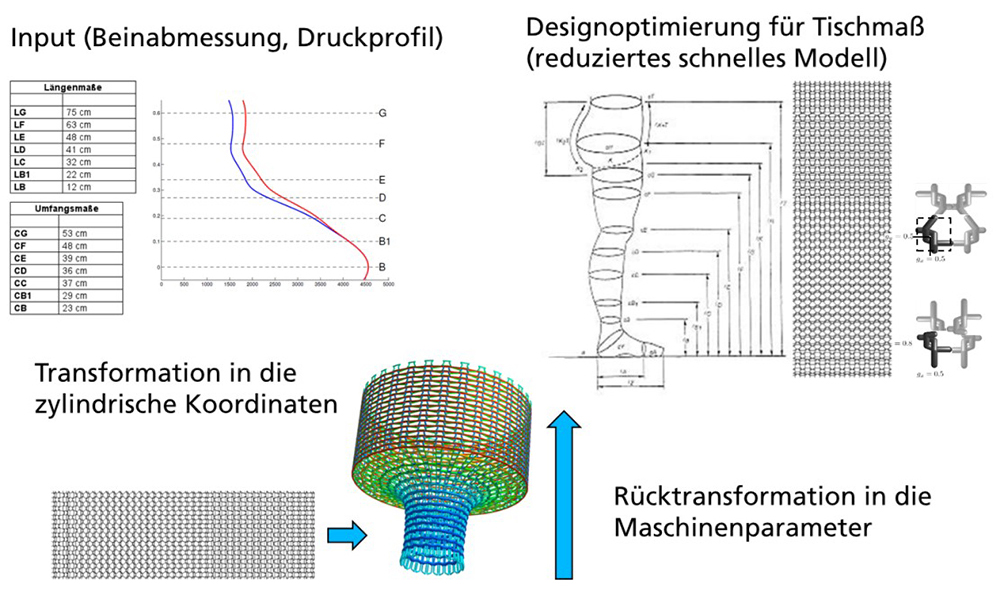

The company BSN medical is manufacturing different products from diverse knitted fabrics, among others tubular knitted compression stockings. The fact that despite of the same basic design diverse models can be developed from the same material is the particular characteristic of these compression stockings.

The Interaction of the Materials Produces Properties

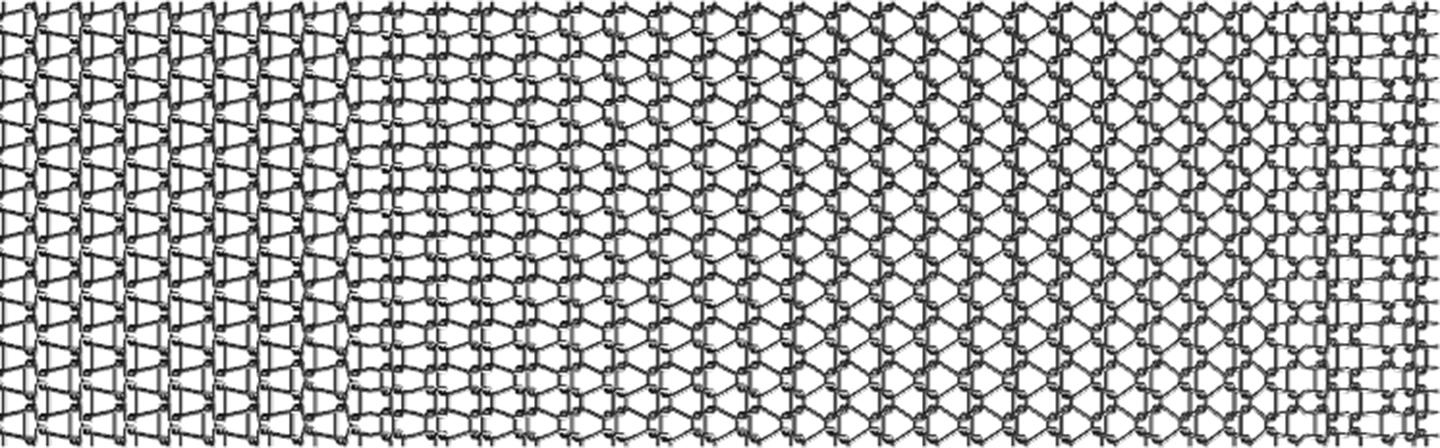

An important characteristic of design of all compression stockings is that in addition to the yarn of the construction another yarn is added; only through the interaction of both yarns the final properties come into being.

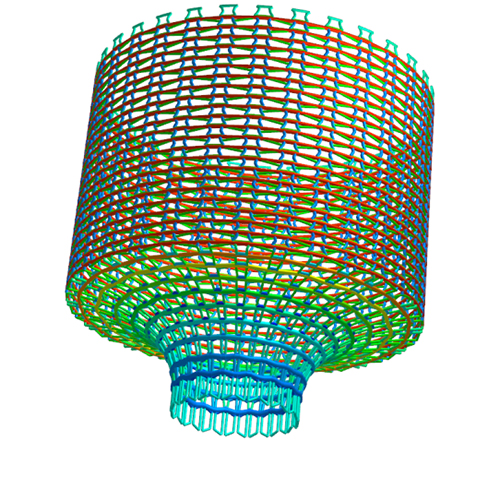

The aim of BSN Medical is to standardize and automatize the process of development that is strongly controlled by experience today. It should be possible for example that a specific compression stocking made from a newly-created material is designed virtually so that for the novel product the original characteristics of compression can be kept. Furthermore, machine parameters can be determined, to modify the compression at defined positions in case of unchanged material. Finally the possibility to design patient-speicific stockings at the computer should be created.

For this aim, ITWM developed special algorithms and implemented them into the own calculation tool TexMath:

- The numerical methods are based on the finite-element-method with non-linear truss-elements that is extended to frictional contact between yarns in this tool.

- The friction force is modelled by means of the Euler-Eytelwein law.

- The non linear problems are solved by two separate Newton procedures, for the elastic deformation and the sliding under friction force.