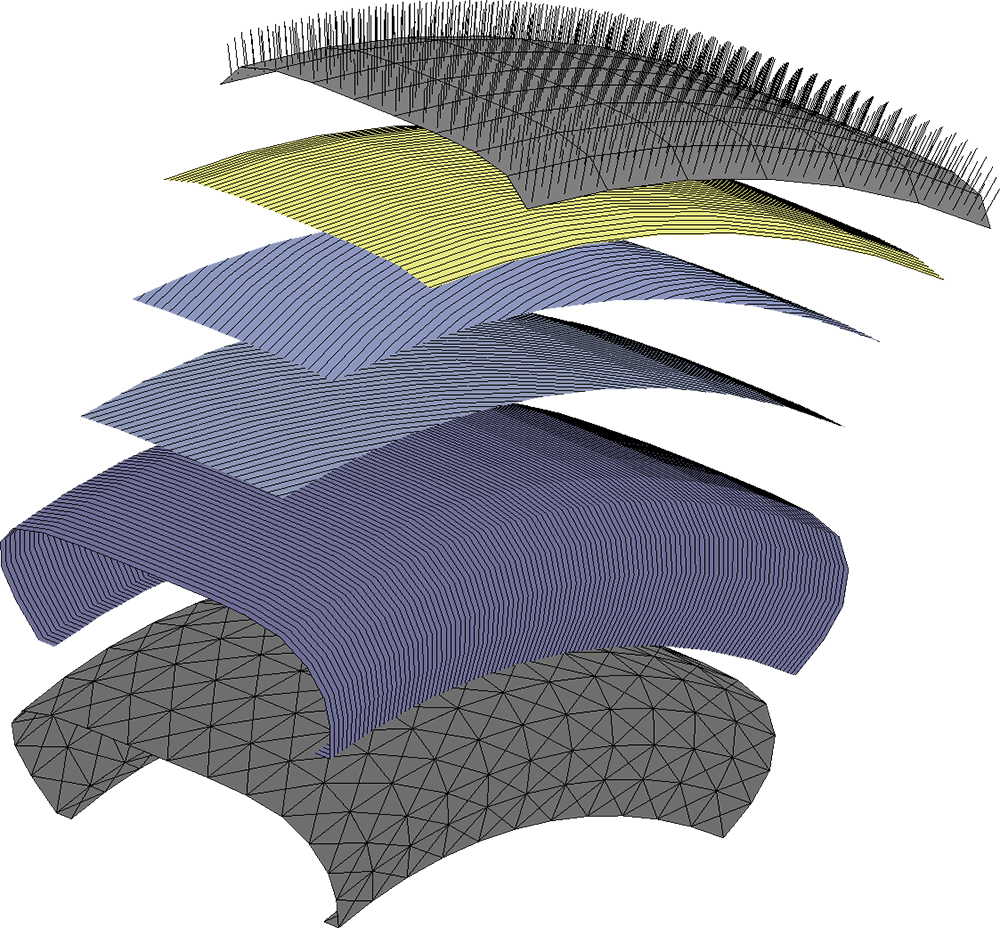

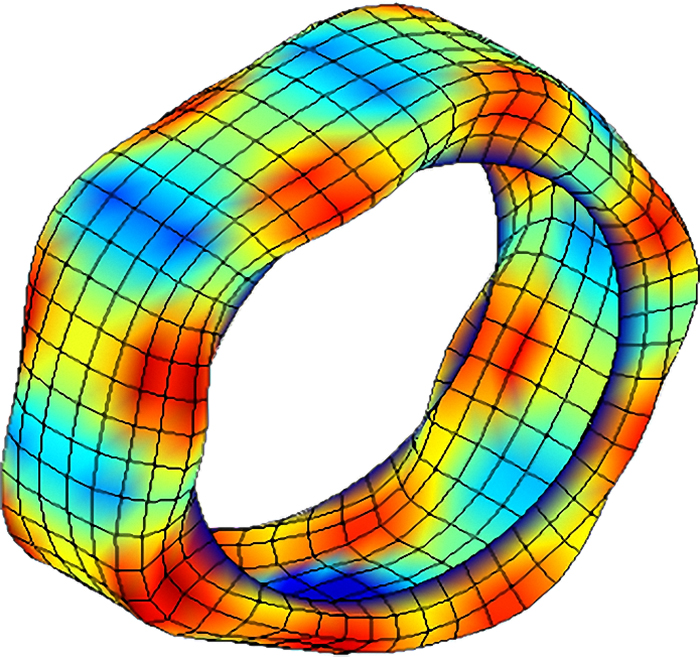

Gallrein, A., Bäcker, M.: Structural MBD Tire Models: Evolving from Spindle Load to Deformation Measurements, in: Proceedings of ECCOMAS Multibody Dynamics 2013.

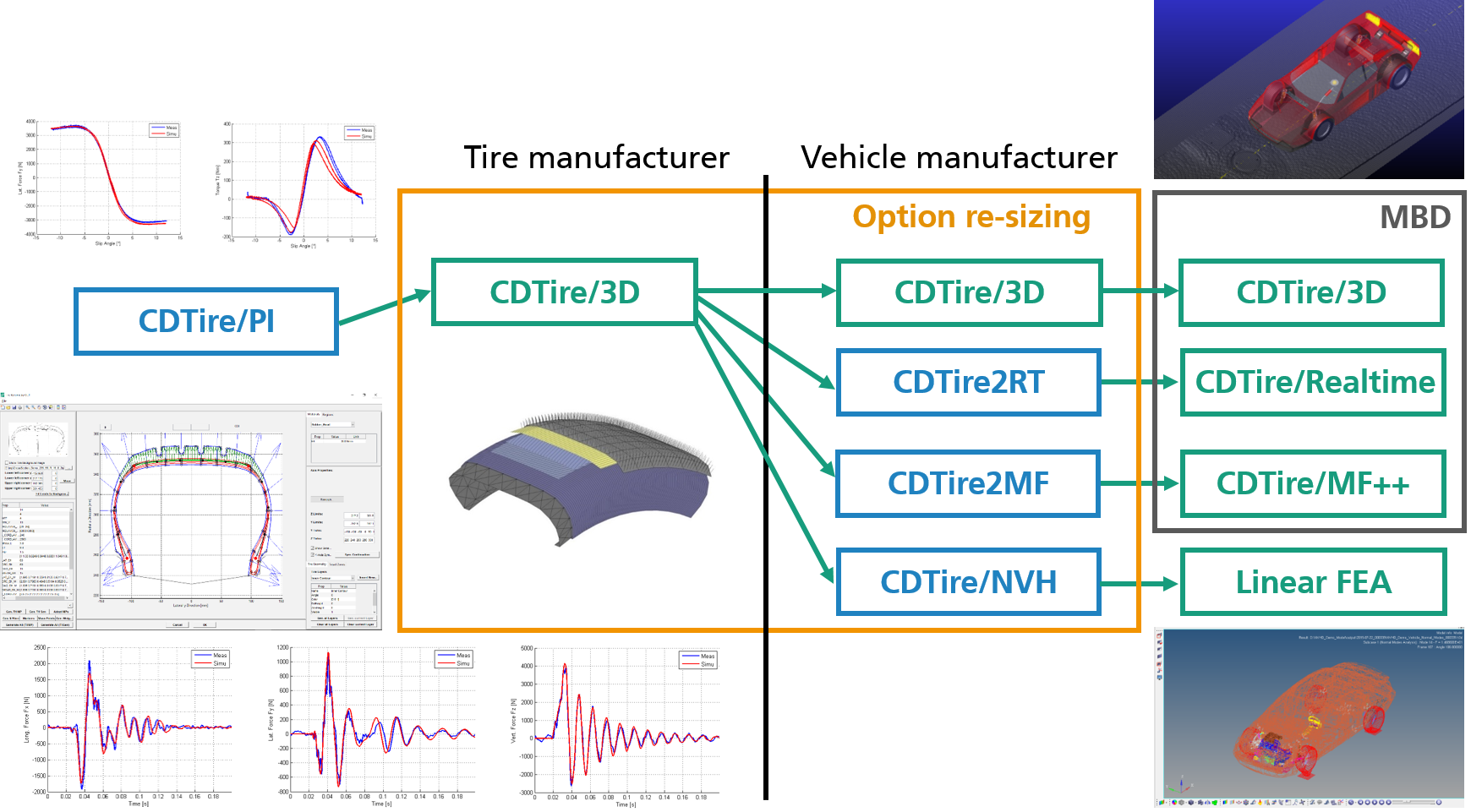

Gallrein, A., Bäcker, M.: CDTire: State-of-the-Art Tire Models For Full Vehicle Simulation, Americas HyperWorks Technology Conference, 2012.

Baecker, M., Gallrein, A., Hack, M., Toso, A.: A Method to Combine a Tire Model with a Flexible Rim Model in a Hybrid MBS/FEM Simulation Setup, SAE Int. SP-2307, 2011-01-0186, 2011.

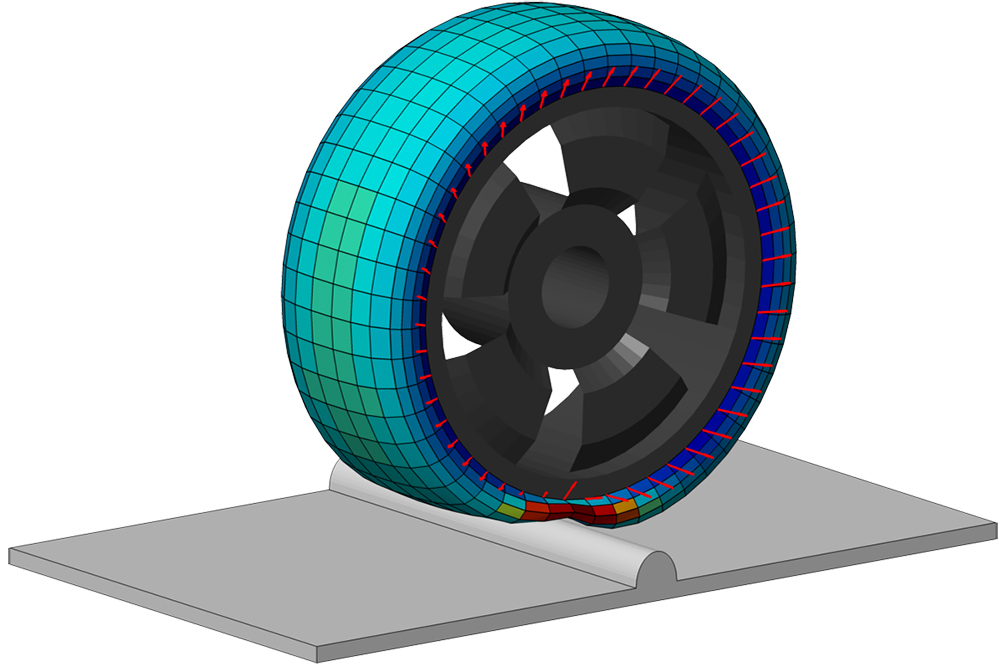

Baecker, M., Gallrein, A., Haga, H.: A Tire Model for Very Large Tire Deformations and its Application in Very Severe Events, SAE Int. J. Mater. Manuf. 3(1): 142-151, 2010.

M. Baecker, A. Gallrein, H. Haga: Simulating Very Large Tire Deformations with CDTire, SAE 2009-01-0577, 2009.

M. Bäcker, R. Möller, M. Kienert, B. Bayram, M. Ozkaynak: Lastdatenermittlung für die rechnerische Lebensdauerabschätzung eines neuen Bustyps, MP Materials Testing 05/2009, Seite 309-316.

H. Haga: Development of Tire Model for Large Input Force, JSAE 20095684, 2009.

Yang, X., Medepalli, S.: Comfort and Durability Tire Model Validation, Tire Science and Technology, TSTCA, Vol. 37, No. 4, October – December 2009, pp. 302-322.

A. Gallrein, M. Baecker, H. Horiuchi, H. Naito: CDTireMC: A New Physical Tire Model for Spindle Load Prediction of Motorcycle Tires Including Very Large Inclination Angles on Rough Roads, 27th Annual Conference on Tire Science and Technology, Sept. 15/16 2008, Akron, Ohio, USA, to appear in Tire Science and Technology, 2009.

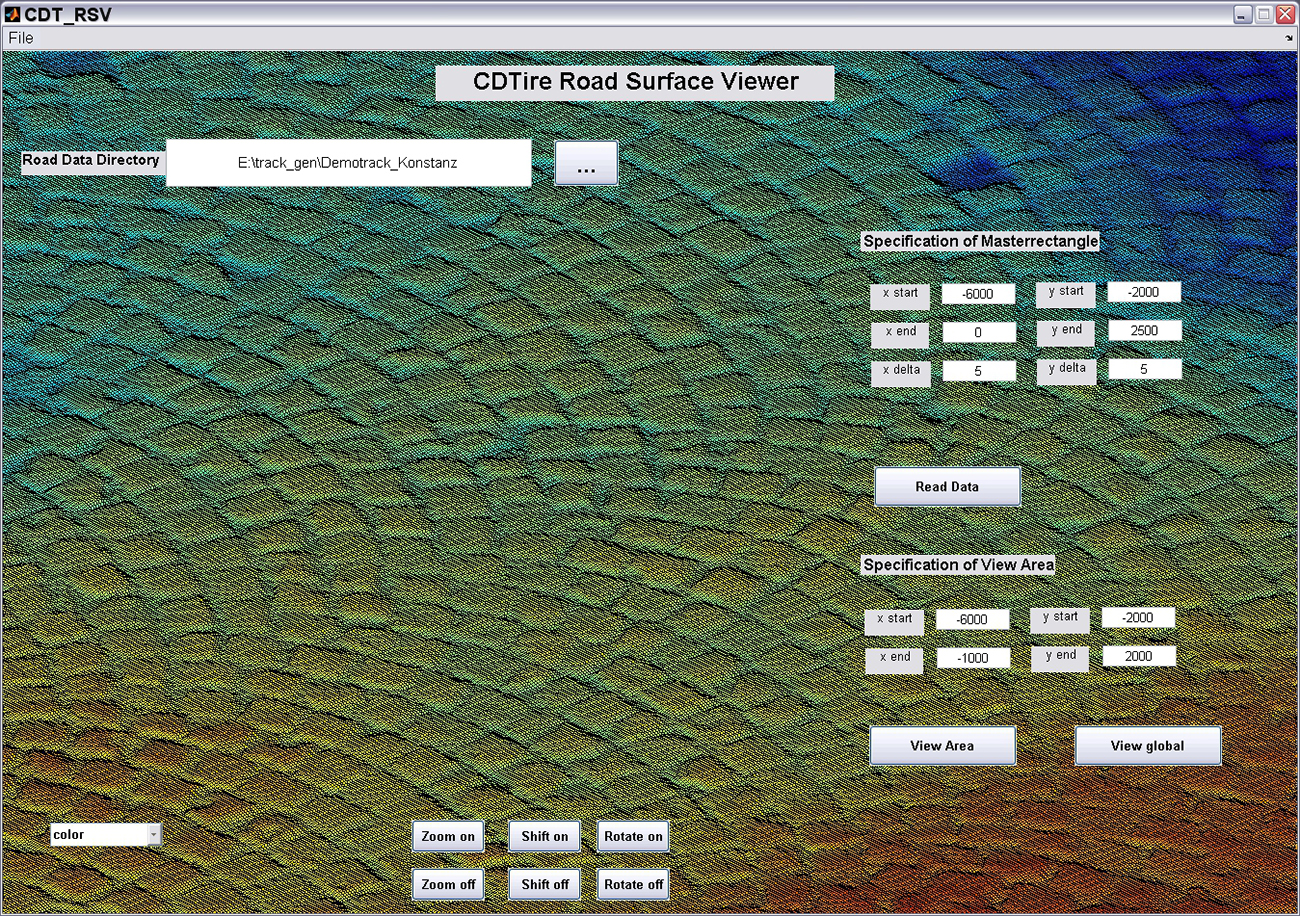

A. Falkner, W. Reinalter, W. Tieber: A validated simulation method for describing the effect of road-excited vibrations on the development of a vehicle, International Journal of Vehicle Design 2008 - Vol. 47, No.1/2/3/4 pp. 3-18.

H. Haga: Evaluation of Road Load Simulation on Rough Road Using Full Vehicle Model (Second Report), 2008 JSAE Annual Autumn Congress Proceedings, No.123-08 p.23-26 (2008).

H. Mauch, A. Ahmadi, W. Rudolph, F.-J. Stolze, M. Baecker, R. Moeller: Numerical and Experimental Simulation of Vehicles on Offroad-Courses, Proceedings DVM Conference "Optimierungs-Potentiale in der Betriebsfestigkeit", Sindelfingen, Germany, October 2008.

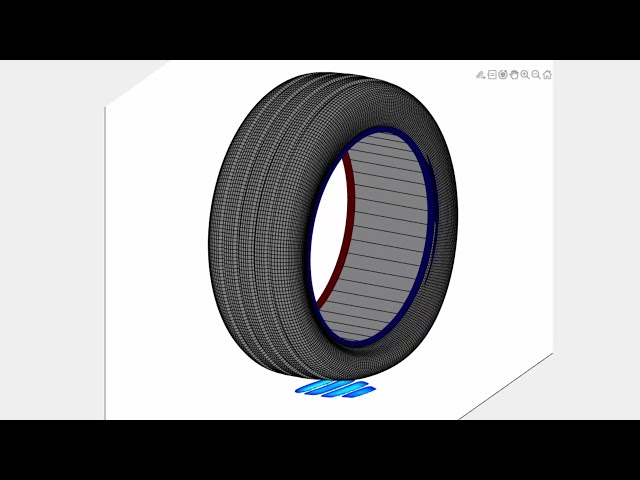

LMS International: LMS Comfort and Durability Tire User Guide, 2007.

S. Heine, C. Hackmair, P. Schneider, A. Wölfl, G. Jung, M. Bäcker: Optimierung von Prüfsystemen mithilfe virtueller Methoden am Beispiel des fahrdynamischen Fahrwerksprüfstandes, MP Materials Testing 09/2007, Page 488-490.

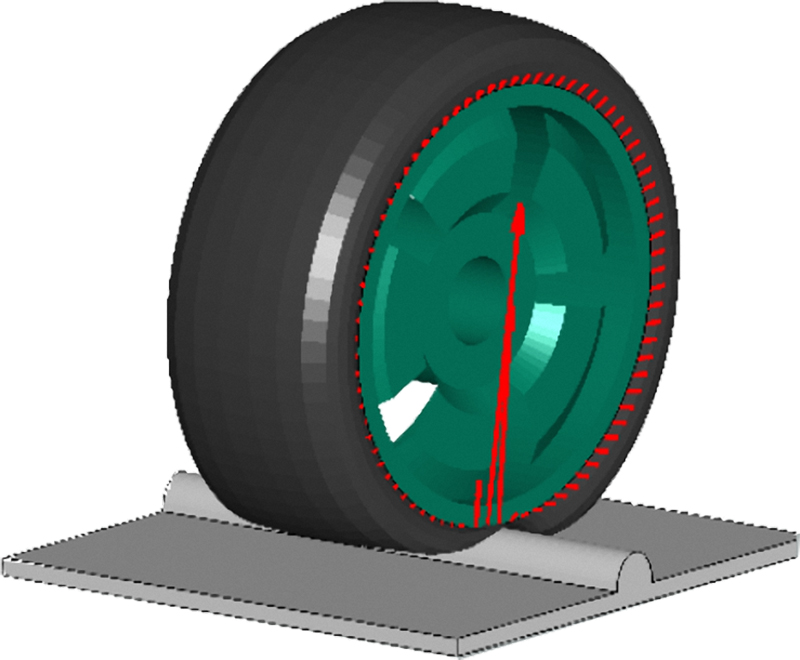

A. Gallrein, M. Baecker: CDTire: a tire model for comfort and durability applications, Vehicle System Dynamics Vol.45, Supplement, 2007, pp.69-77.

H. Haga: Evaluation of Road Load Simulation on Rough Road Using Full Vehicle Model, 2007 JSAE Annual Autumn Congress Proceedings, No.123-07 p.21-24 (2007).

H. Haga : Evaluation of Road Load Prediction by Multi-body Simulation Including Flex-Body (Second Report), 2006 JSAE Annual Autumn Congress Proceedings, No.136-06 p.11-14 (2006).

H. Haga : Evaluation of Road Load Prediction by Multi-body Simulation Including Flex-Body, 2006 JSAE Annual Spring Congress Proceedings, No.21-06 p.9-12 (2006).

H. Haga : Evaluation Method for Road Load Simulation, 2005 JSAE Annual Spring Congress Proceedings, No. 27-05, p.9-12 (2005).

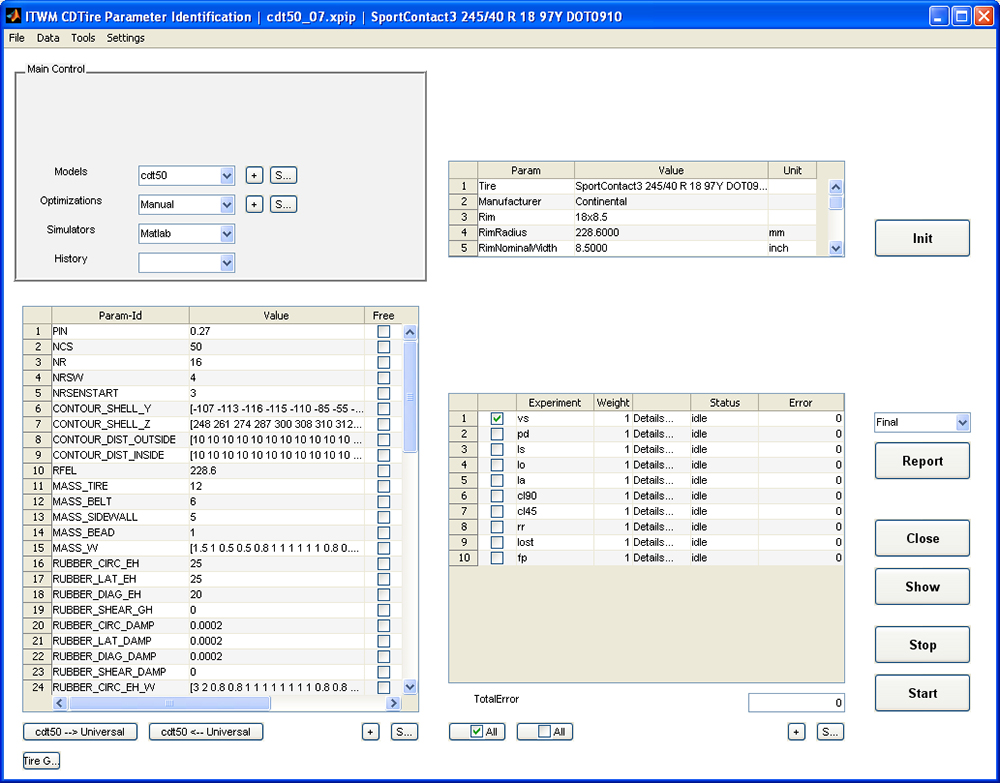

A. Gallrein, J. DeCuyper, W. Dehandschutter, M. Baecker: Parameter Identification for LMS CDTire, 3rd Int. Tyre Colloquium, Tyre Models for Vehicle Dynamics Analysis Proceedings, Vehicle System Dynamics Vol.43, Supplement, 2005, pp.444-456.

H. Haga: Evaluation Method for Road Load Simulation Using a Tire Model and an Applied Example, 3rd Int. Tyre Colloquium, Tyre Models for vehicle Dynamics Analysis Proceedings, Vehicle System Dynamics Vol.43, Supplement, 2005, pp.281-296.

H. Haga: Evaluation of Tire Models for Durability Loads Prediction Using Suspension on Drum Environment, 2005, SAE 06M-266.