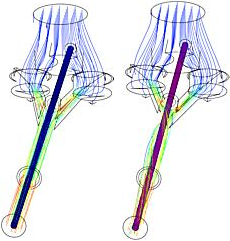

In machines for the production of carpet fibers, the filaments are first stretched over heated galettes, accelerated subsequently in one or more air shafts by diagonally injected air flows, and finally joined in a lamellar channel for frilling. In order to optimize this well-functioning process, it is the objective of our project to examine the air flow in the so-called texturing nozzle in detail. Thus, the nozzle can be improved with respect to:

- air consumption,

- tensile load of the filament

- and twist effects.

The air flow in the texturing nozzle can be described by the conservation equations for mass, momentum and energy, combined with the ideal gas equation. This leads to the compressible Navier-Stokes equations. In the nozzle, the string of filaments is represented as a cylindrical dome, in order to simplify the geometry.