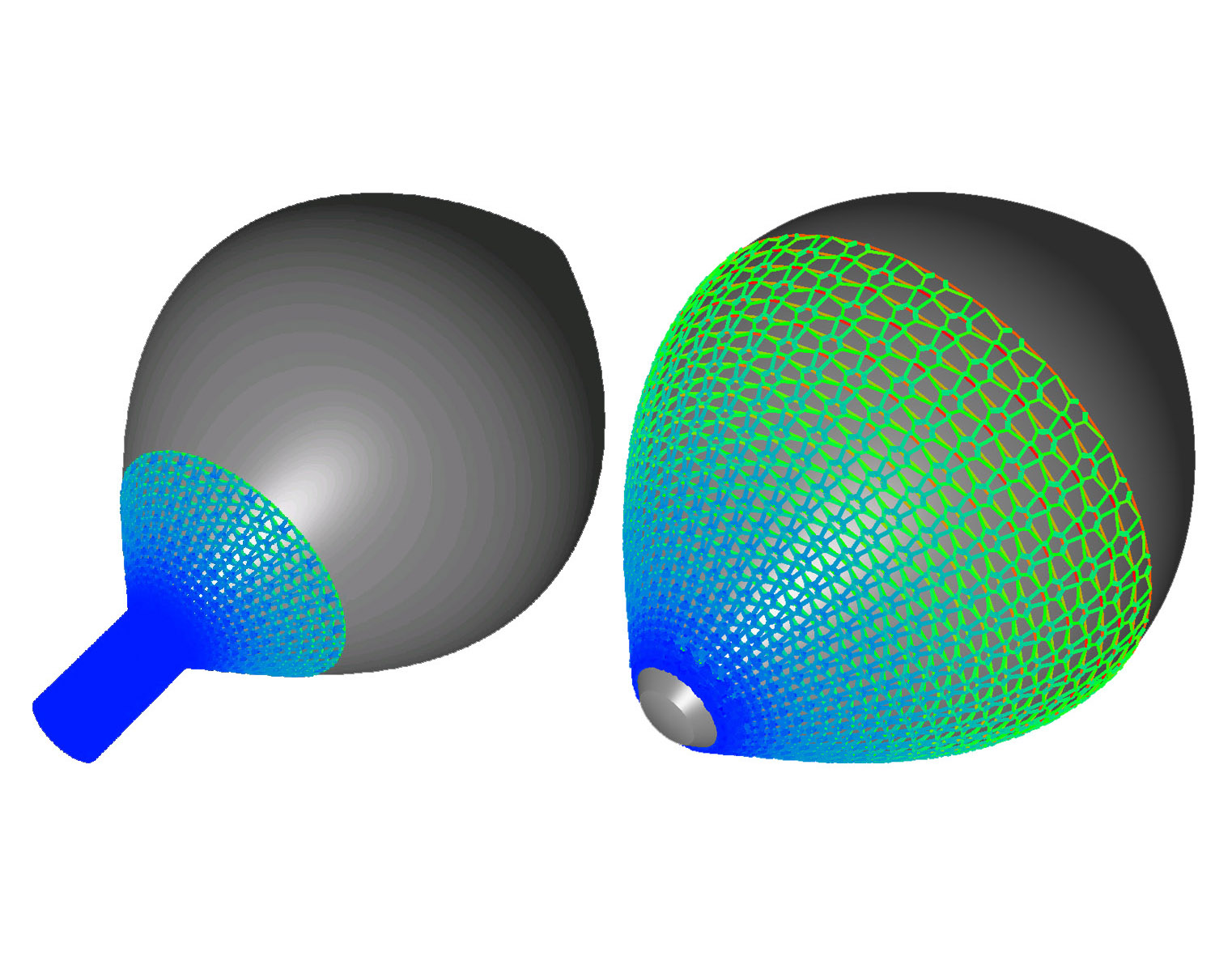

Fiber-reinforced plastics are the basis for many applications in state-of-the-art lightweight design, and they offer numerous advantages. One major obstacle for smaller companies, however, is the requisite know-how concerning the ideal fiber and textile arrangement. In collaboration with the Institut für Textiltechnik (ITA) and the Assoc. Institute for Management Cybernetics (IfU) in Aachen, the Fraunhofer Institute for Industrial Mathematics ITWM has now developed a mathematical simulation method for optimizing the drapability (deformability) of textiles.

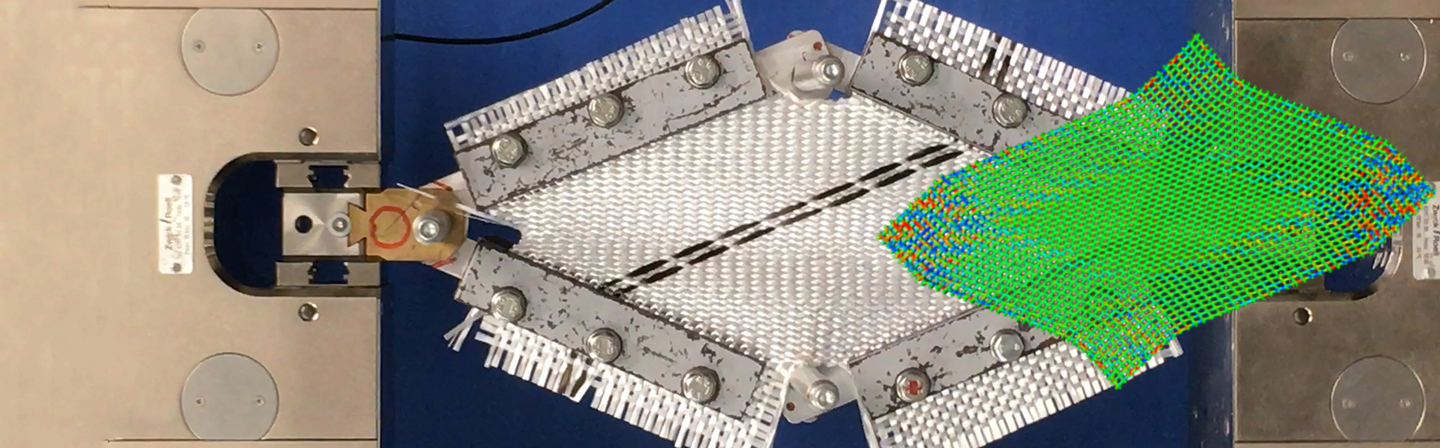

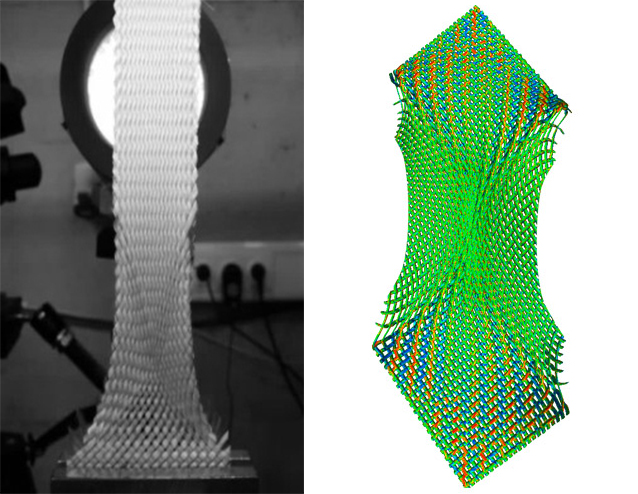

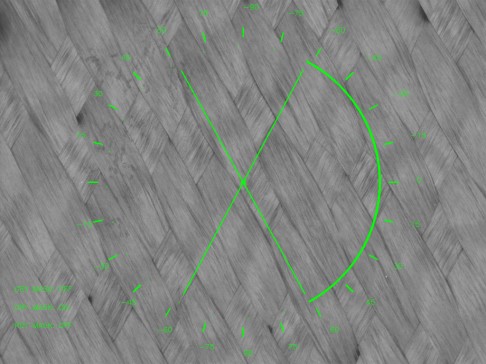

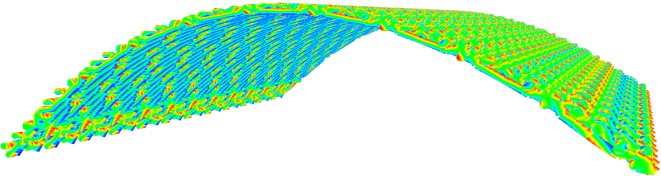

The potential of components made from fiber reinforced polymers (FRP) is highly dependent on the type of reinforcing textiles used and their drapability (ductility). The draping quality is evaluated on the basis of defects and wrinkles in the textile after preforming. Preforming refers to the process for producing a dry reinforcement structure. The potential of the anisotropic material is enormous for lightweight construction and can be specifically exploited only if the textile fibers are present locally in the required orientation. The draping process takes place during the production of complex geometries by experienced specialists. From a technical and economic point of view, the process lacks standards and objective criteria and requires optimization.