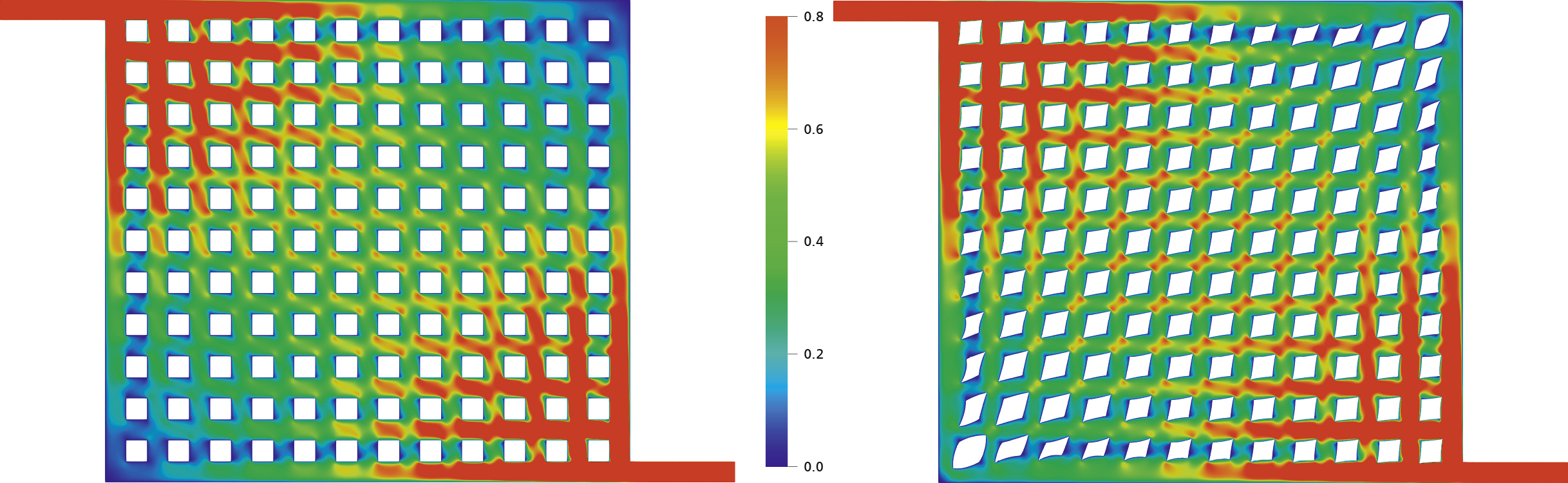

Hydrogen technologies are seen as paving the way for climate-neutral mobility and as holding out hope for the climate-neutral design of the energy industry and the chemical industry. But to achieve this, the chemical processes of the cells need to be better understood. A team from the department »Transport Processes« led by Dr. Christian Leithäuser supports the design and optimization of the cells with novel simulation methods. As part of the project »H2-D – A Hydrogen Economy for Germany«, they are focusing on the shape design of bipolar plates.

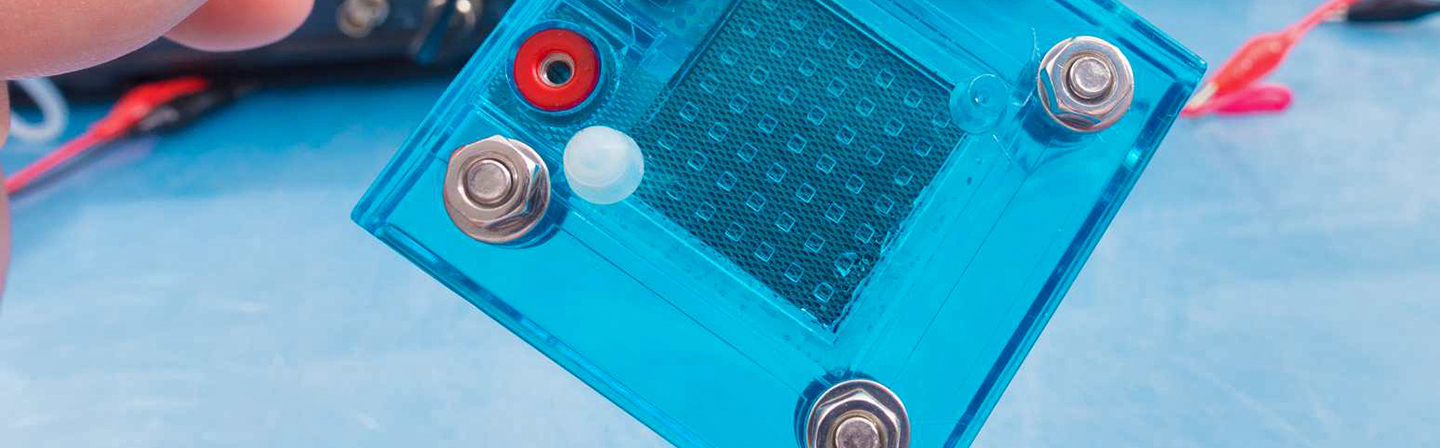

The fuel cell seems to be the ideal vehicle drive: quiet, clean and independent of oil. The hydrogen required for this can be obtained from green electricity via electrolysis. An electrolysis cell is similar to a fuel cell, except that the entire process is reversed: Using electrical energy, hydrogen is obtained by splitting water into hydrogen and oxygen. Among other things, a cell consists of two metallic plates (bipolar plates) and a membrane. The flow dynamics of the bipolar plate are quite crucial for the performance of the cell. Our team want to design these in such a way that the oxygen produced is discharged sufficiently quickly to make the cell more efficient. To do this, they simulate a multiphysics problem and use shape optimization methods.