Nonwovens now play a central role in many industries, for example in the automotive industry, healthcare, medicine, construction and filtration. The demand for these versatile materials continues to grow. In production, simulations are helping to further develop the important airlay technology for staple fibers. In the current cooperation, three companies have joined forces to optimize the carding machines in this process: bematic®, Siriotek and our Fraunhofer ITWM team from the »Transport Processes« department. Together, we are carrying out feasibility studies on the latest »AioLos« airlay design from bematic® in order to further optimize it.

Optimizing the Production of Nonwovens and Airlay Technology Thanks to Simulation

bematic®, Siriotek and the Fraunhofer ITWM Are Working Together to Advance Nonwoven Production Technology

Faster, More Economical and More Efficient Processes

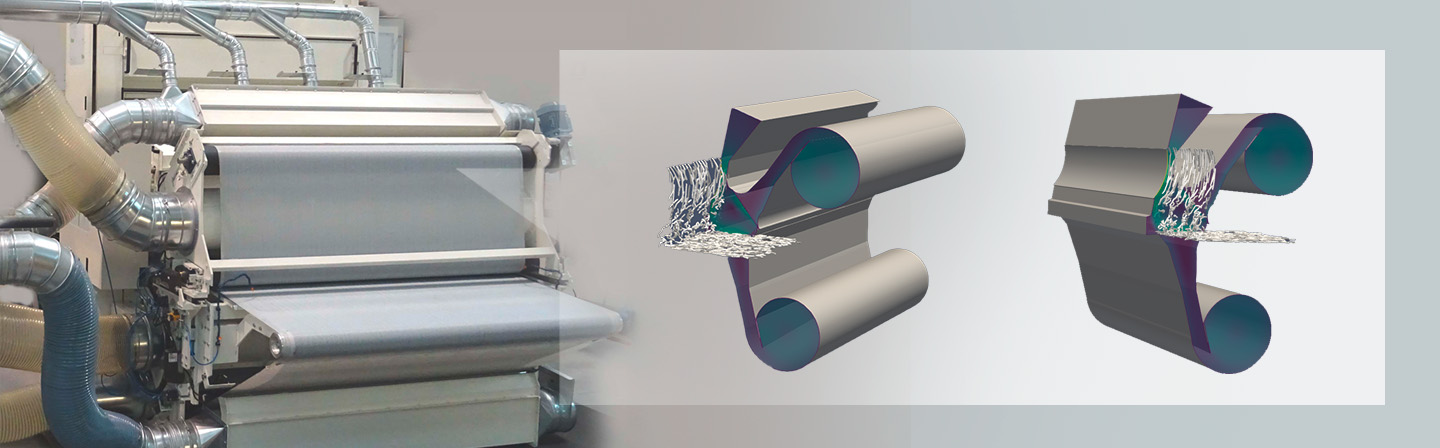

In the joint cooperation, new types of carding machines are being developed that ensure performance and quality in airlay processing with staple fibers while generating less energy, waste and carbon emissions. A brief description of the process: Airlay technologies are used to process a broad spectrum of fibers, possibly including recycling fibers, to produce nonwoven materials. The raw material is opened and fed into an air stream using a roller (see video). This air-fiber mixture is deposited on a belt using a suction, compacted, and then bonded thermally, mechanically, or chemically. The collaboration between the three companies combines the specialist knowledge and innovative strength of their respective expertise.

Feasibility Study with Simulation

As part of ongoing collaborative efforts focusing on development and optimisation of production technologies for nonwovens, Fraunhofer ITWM and Siriotek have completed feasibility investigations on bematic® latest airlay design »AioLos«. The study aimed at simulating fibre dynamics inside the airlay to provide insights and data useful for optimising productivity and efficiency of the production process. It consisted of two sequential stage.

1. Analysis of the Airflow Across the Web Forming Cavity

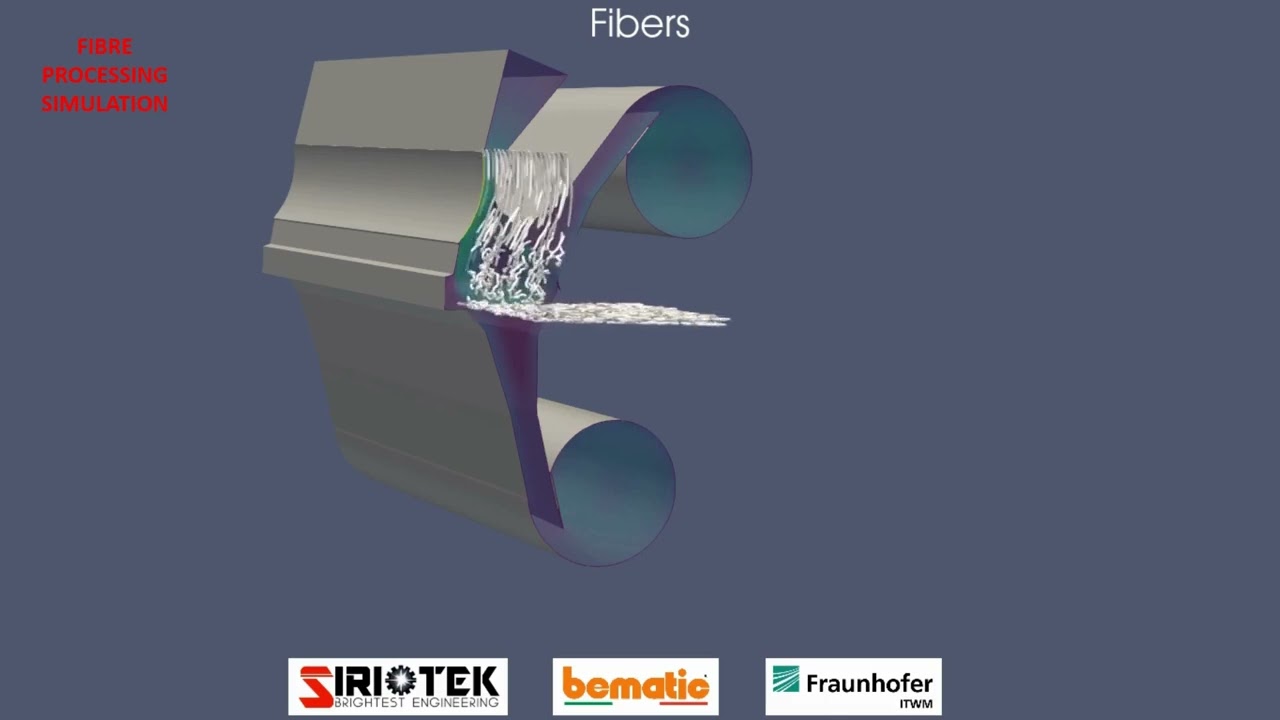

A detailed CFD model was developed by Siriotek engineers which includes moving boundaries to simulate rotation of the main carding drum as well as linear motion of the porous belts designed to promote web formation and transport of nonwoven fabric.

2. Simulation of the Fibre Deposition Process

Results from the CFD analysis were passed to Fraunhofer ITWM for use with their proprietary software FIDYST (FIberDYnamics Simulation Tool). Using material data, density and size for polyester fibres scientists at Fraunhofer ITWM were able to predict motion of the fibres inside the airlay forming vane under the effect of turbulent airflow resulting from the CFD analyses performed at Siriotek, effectively simulating the deposition process on porous moving belts. A detailed technical description of the dynamic model predictive capabilities can be found in the articles in the infobox.

Video: Cooperation: Optimizing Airlay Processes with the Help of Simulations

Cooperation: Optimizing Airlay Processes with the Help of Simulations

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyCooperation: Simulations Optimize Airlay Production Processes in the Production of Nonwovens

Outlook: Study Creates the Basis for New Units

The feasibility study also included further investigations covering process speeds as well as optimal design for the carding wire to be installed on main drum and worker/stripper rollers operating upstream of the airlay aerodynamic vane. Results have been very encouraging and bematic® have now committed fully to the new design by confirming manufacturing of a full scale unit, with procurement of parts currently in progress.