The chemical industry is not only an important branch of industry in Germany, but also a significant driving force for product development and innovation in the areas of energy and resource efficiency – and therefore also for climate protection. Society and politicians are calling for »Green Chemistry«, for which intensive research and development efforts are indispensable. Our researchers are investigating how this green chemistry can be advanced with digitalization.

Some of the work carried out by our research team involves the optimization of flow fields in electrochemical reactors. These play a central role in sustainable energy generation and chemical synthesis. The optimization of the flow fields aims to increase the efficiency and performance of such reactors.

Importance of Optimizing Flow Fields in Electrochemical Cells

Practical applications of electrolysis cells include the production of green hydrogen and other chemicals and fuels. At the partner institute Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT, these cells are used for electrochemical hydrogenation (EChH). Electrosynthesis offers a sustainable alternative to conventional processes. The flow fields are responsible for distributing the fluids required for the electrochemical reaction across the entire cell.

At the same time, they have to meet high requirements in terms of mechanical stability and electrical conductivity. Our optimization of the flow fields can therefore significantly improve the efficiency of the reactions in the cells.

Methods: Simulation Models for Optimizing the Flow Fields

Expertise from three Fraunhofer ITWM departments was brought together for the flow simulation and optimization:

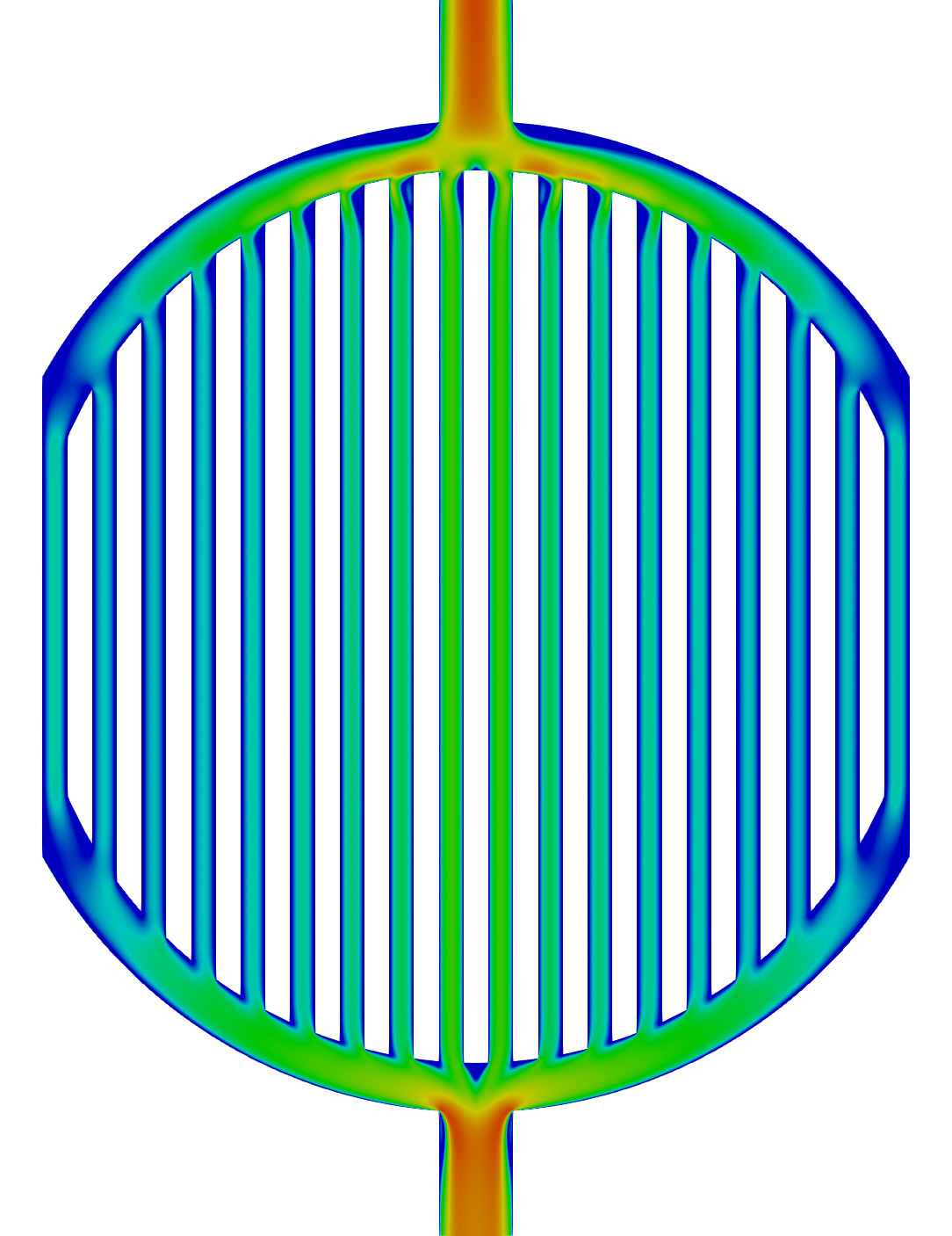

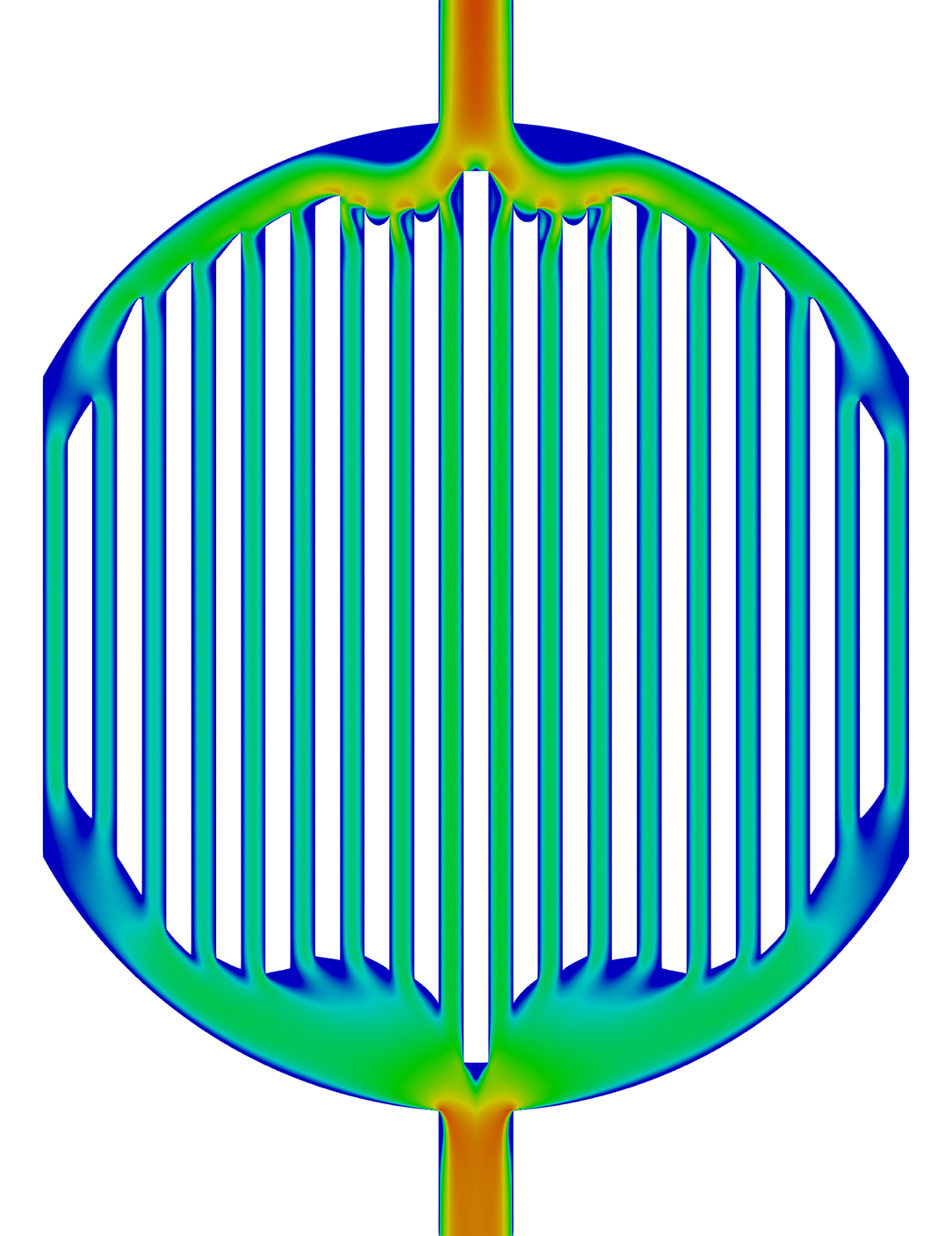

- The »Flow and Material Simulation« department develops detailed simulation models of flow and electrochemical reactions.

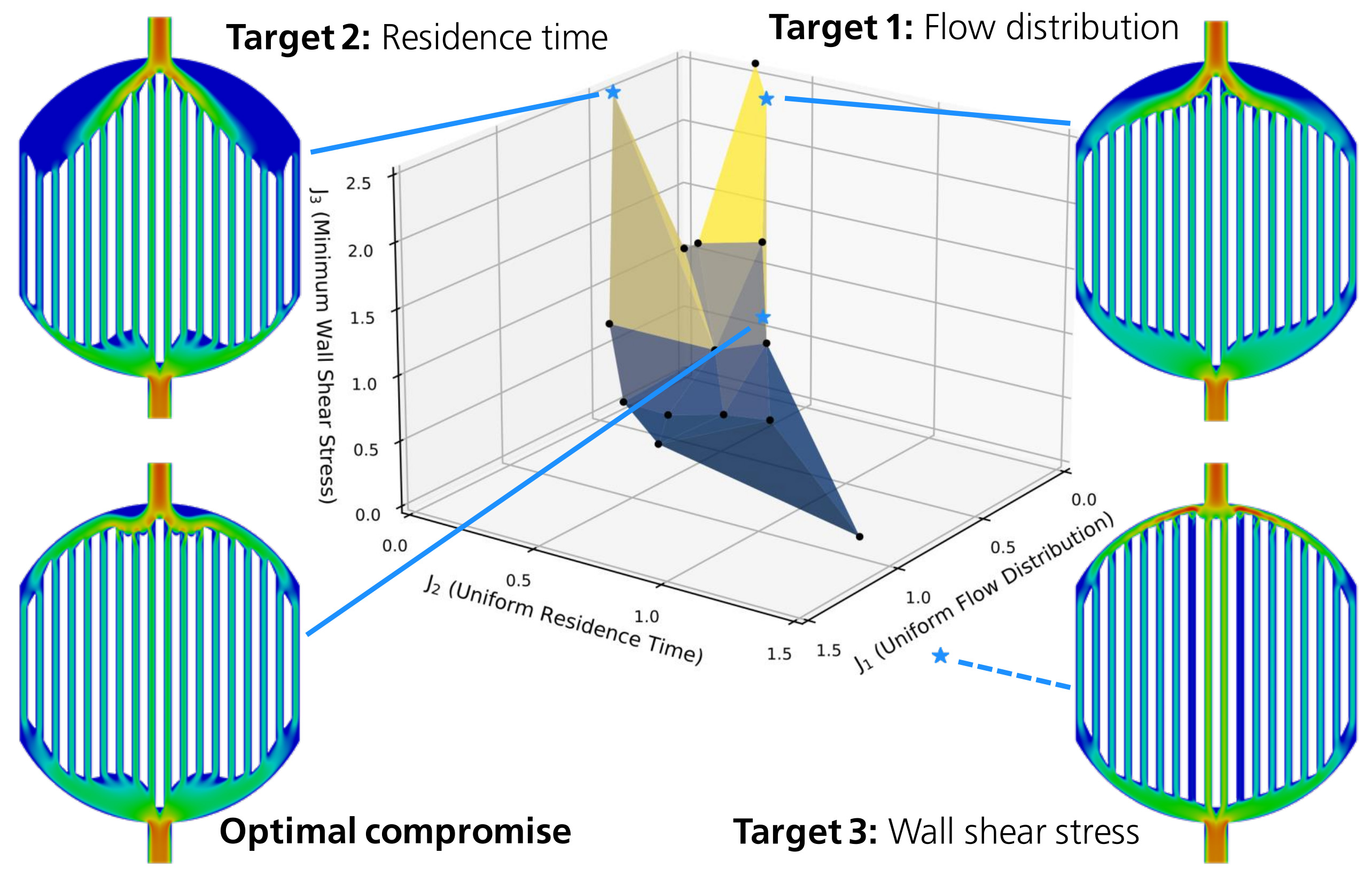

- The »Transport Processes« department uses shape optimization methods to generate new designs for the flow fields.

- The »Optimization« division provides algorithms for multi-criteria optimization.