Although paper and paperboard seem to be homogeneous in appearance, on a microstructure level they are complex materials, consisting of cellulose fi bers, fi ne fi bers, and fi llers. Strictly speaking paperboard is also paper, albeit a paper with a grammage of more than 150 g / m2. The aim is to generate a virtual fi ber structure with fi llers using a microstructure simulation. Additionally, it should be possible to perform predictions regarding the material properties. The paper industry can develop innovative methods using such predictions, which in turn, lead to optimized manufacturing processes and products.

Generating Virtual Structures for Paper and Paperboard

Fraunhofer ITWM develops the Structre generator PaperGeo, which satisfies the requirements mentioned above and is also a module of the existing software suite GeoDict. PaperGeo enables microstructure models of paper to be generated. Tomography and SEM images provide the basis for the modeling, which facilitates the specifi cation of material distribution, fi ber cross-section and orientation, and percentage of fi ller particles, etc. in the paper.

Microstructure Model with PaperGeo

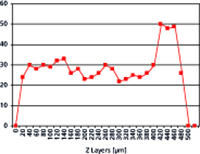

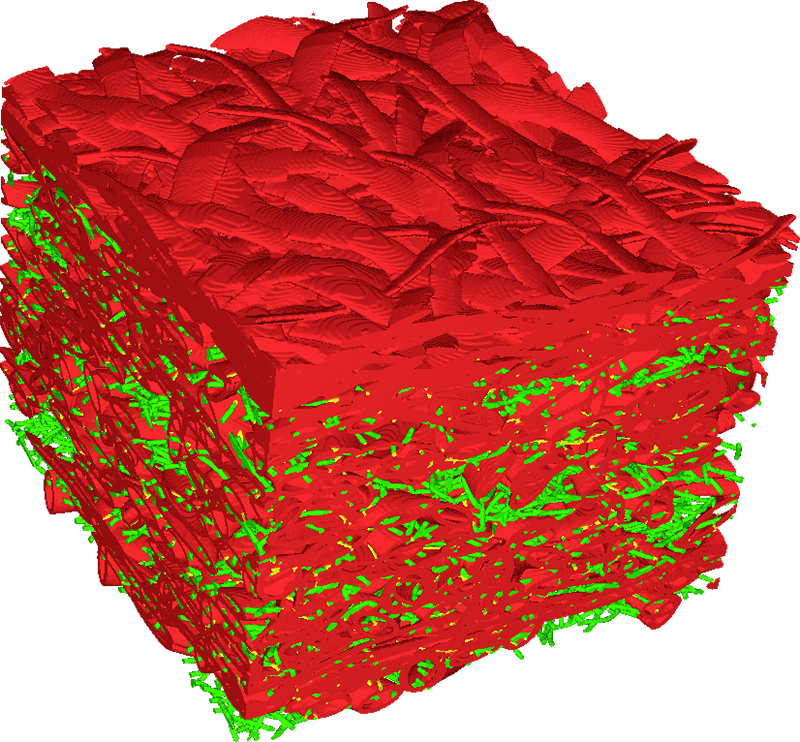

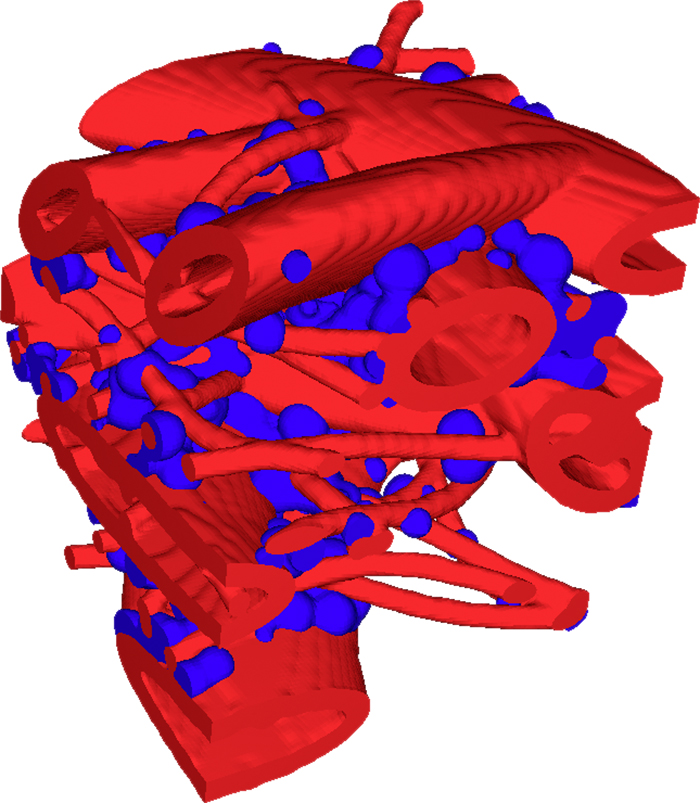

Figure 1 shows the material density distribution of a two-ply paper as found in this analysis. It is evident that the upper layer has a higher percentage of fi ber than the lower layer. Using the extracted information, PaperGeo generates a microstructure model that also accounts for the fine fibers (Figure 2). The rough fibers are shown in red and fine fibers are colored green. By using variable parameters, different paper characteristics, for example, permeability can be examined, although we have focused in particular on the infl uence of potential filler particles. The result is illustrated in Figure 3 with the filler particles shown in blue.

Meanwhile, several well-known companies have selected PaperGeo. Among them are Albany International, Eka Chemicals, Stora Enso, Tetra Pak Packaging Solutions AB, and Fraunhofer Chalmers Centre (FCC). In this case, an interface is developed to allow the extracted effective parameters to be run for the purpose of performing a macro-simulation of edge-wicking (moisture induced edge corrugation). The software development follows a general approach making it also possible to simulate other fiberous products, like fabrics and nonwovens. Meltblown media are one example.

Models for Paper Fibers and Spherical Packing

One of the difficulties with sphere packings is the great variation in sphere sizes. On the one hand these variations are intentionally used for the material design, one example are construction materials. On the other hand they occur in real media like the fill material of dams or in natural soil. As a result of these variations, given size distributions can only be realized with very large numbers of spheres. To maintain high packing densities for these large numbers of spheres, meaning solid volume fractions of over 60 per cent, unacceptably long computing times were required in the past.

With improved algorithms, these times have been reduced to a few hours for realistic examples. The model for paper fibres was developed, because the existing model of straight fibres with a constant cross-section was not sufficient to model real cellulose fibre media. Paper fibres have great fluctuations in fibre width, irregularities in cross-section form and local bends, which can be precisely reproduced in the new model. Cellulose fibre media with high density have only become possible through a change of the structure-generating mechanism.

Simulation of Structural Properties

For all µCTS, whether it involves sphere packings, cellulose fibres or other materials, the properties resulting from the geometry are important. Since real CTs and µCTs can be treated identically by a computer program, comparing all calculated properties with one another is no problem at all. The uniform representation as µCTs also enables all properties to be calculated for all material types. All structures and properties can be simulated with the GeoDict software. Thereby all calculations can also be performed by our partners.