In many industrial processes, there is still undiscovered potential for improvement - for example, in terms of the yield of a target product and the energy required to produce it. Identifying this potential is of crucial importance, especially in times of scarce resources. We develop reliable, easy-to-use and individually tailored software for the simulation and optimization of dynamic processes in process engineering. Our software products allow the users to interactively discover potential for improvement and support them in finding optimal solutions.

Software for Batch Distillation

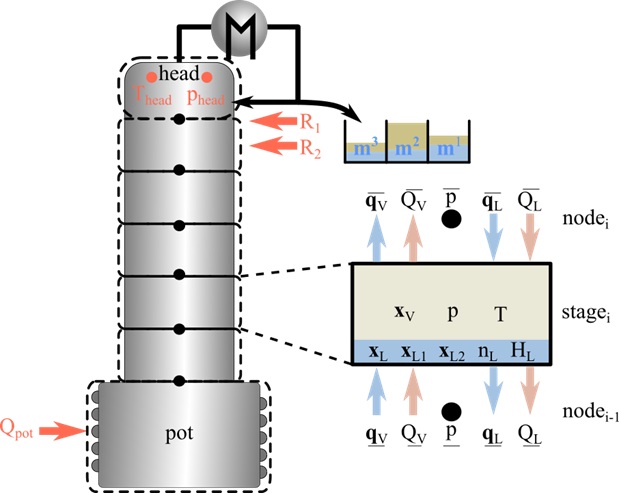

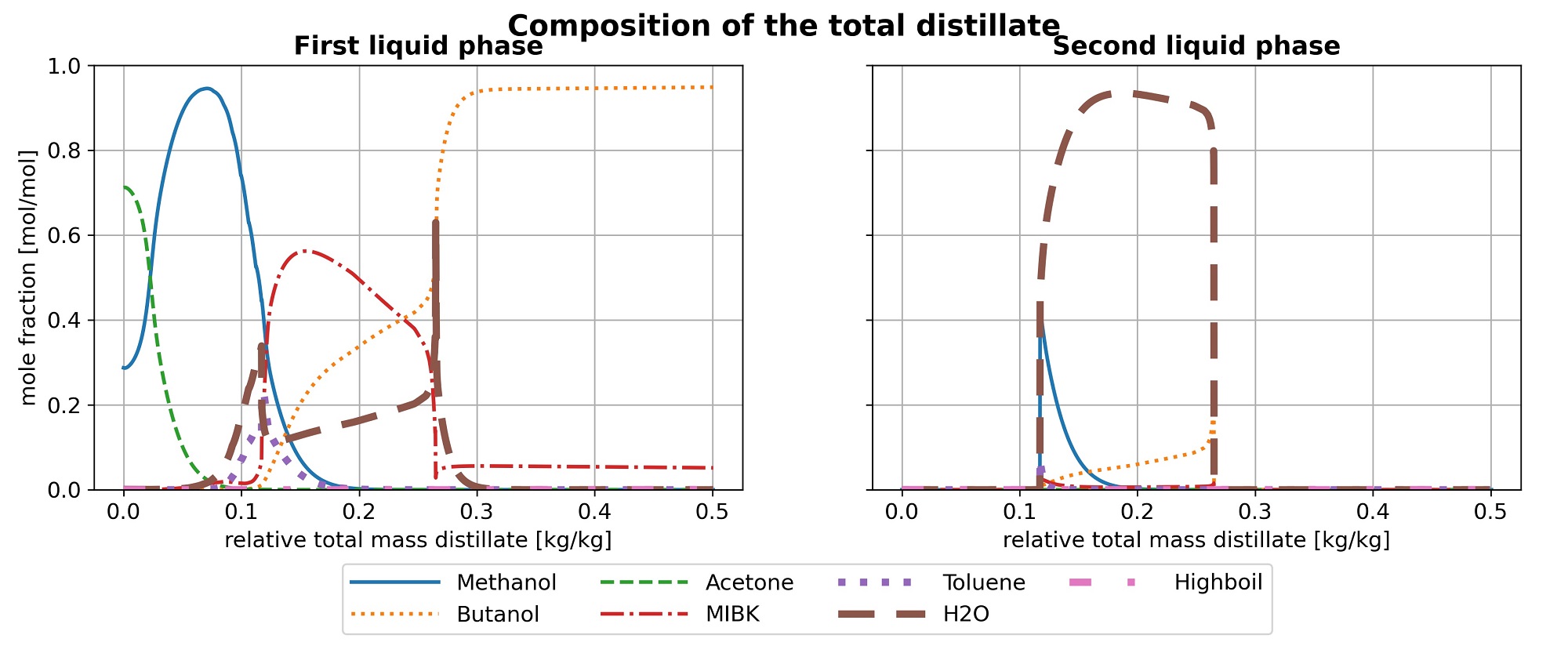

A team from the departments »Optimization - Technical Processes« and »Transport Operations« is developing a software package for the simulation and optimization of batch distillation processes at industrial companies. Batch distillations are used to produce high-purity chemicals from relatively small batches of an initial mixture composed of several substances. For this purpose, the mixture is filled into the bottom of a distillation column and heated there. Due to the different boiling temperatures of the individual substances, they evaporate at different rates and thus reach the condenser at the top of the column at different speeds. In this condenser, the incoming vaporous mixture of substances is liquefied again and then partly withdrawn into various fraction containers and partly refluxed to the column.