Our digital twin enables heat suppliers to ensure a consistently efficient network operation – even under increasingly complex operating conditions with decentralized feed-in – while ensuring its stability and security of supply.

»AD Net Heat« Software Solution for District Heating – Dynamic Simulation for the Networks of Tomorrow

Monitoring and Optimizing District Heating Networks With Digital Twin

»AD Net Heat« Simulates and Optimizes Operation of District Heating Networks

Current software for operational support of combined heat and power plants either deals with the optimal use of local operating resources, treating the heating network only as a structureless sink. Or software is used for spatially resolved thermo-hydraulic simulation of the heating networks, which, however, usually neither captures dynamic runtime effects nor allows for operational optimization. This is where »AD Net Heating« comes in.

The dynamic simulation of the district heating network has enormous advantages: The network operator can use the software to monitor both the temperature and the flow conditions at any point in the district heating network at any time. This allows to control the feed temperature provided at the power plant and the mass flow pumped into the network and thus prevents, for example, gas boilers from having to be switched on at high cost to produce heat.

Mathematics Behind the Software Creates Digital Twin

Classical methods for solving the fluctuating thermo-hydraulic equations are too inaccurate or time-consuming to provide optimized controls for live operation of the district heating network.

Privacy warning

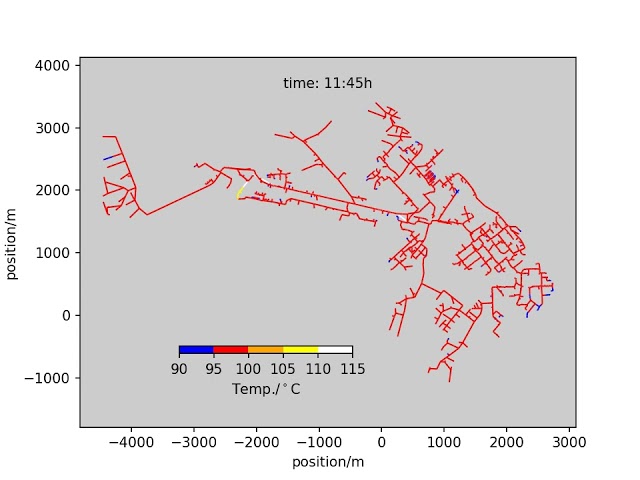

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyDynamic simulation of the inner-city network of the Technische Werke Ludwigshafen. Temperature in the district heating network. © Fraunhofer ITWM

For this reason, we have developed our own efficient numerical method for solving the equations on the pipeline network for »AD Net Heat«, which can handle optimization horizons of several days. Based on the software, we create a digital twin of real existing district heating networks. This couples efficient dynamic flow simulation with robust consumption forecasting using artificial neural networks, model predictive control and modern measurement sensor technology. Due to the model-based approach, the digital twin is able to propose optimal controls for live operation even with low sensor coverage, significantly exceeding the wealth of experience in previous control routines and consumption situations. Given the decentralization of feed-in locations and the on-going expansion of the grid, this capability is more important than ever.

Privacy warning

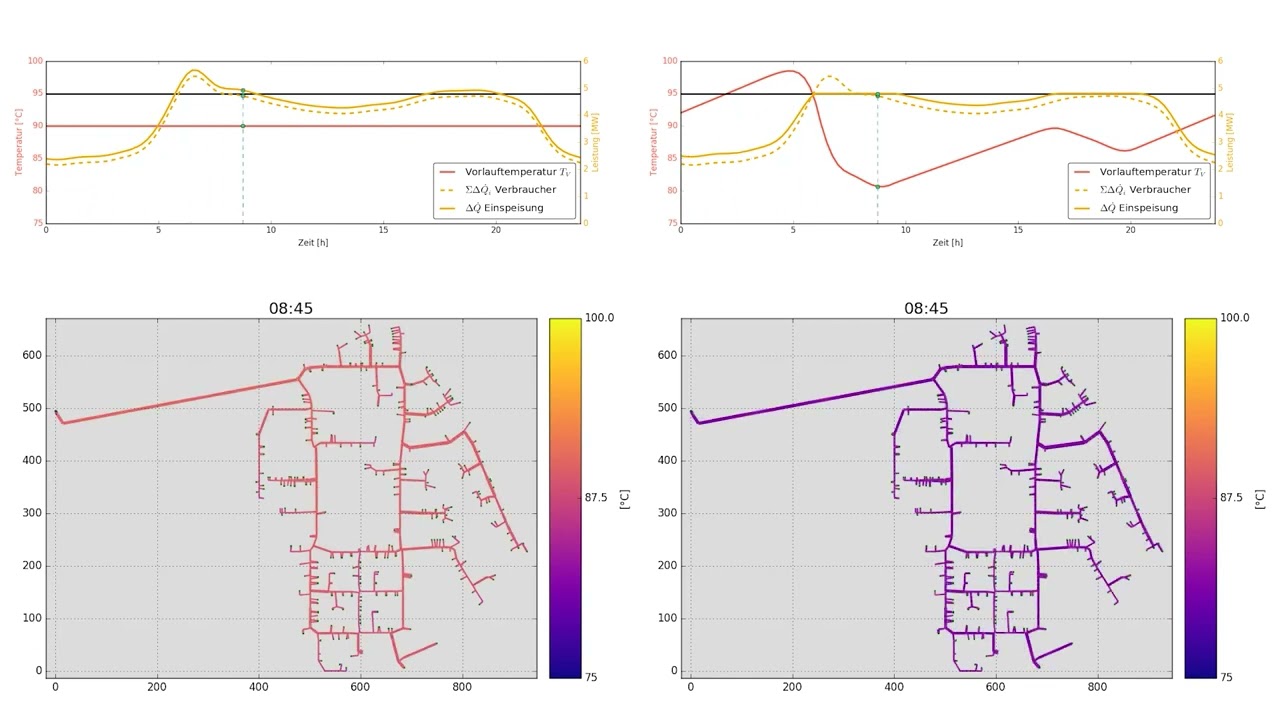

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyOptimized simulation of the subnetwork »Im Neubruch« in Ludwigshafen with our district heating software tool »AD Net Heat«. Comparison of data: Feed temperature (solid red line), demand power (dashed yellow line), feed power (solid yellow line). © Fraunhofer ITWM

Furthermore, our district heating network software »AD Net Heat« offers enormous potential for network expansion planning. By relying a model of the network and the underlying thermo-hydraulic equations, we can analyze future expansion scenarios in detail even before measurement data from operation are available, in contrast to purely data-driven analyses. Suppliers can thus make well-informed decisions early on and use resources optimally.

Digital Twin Supports District Heating Transformation

As the transition of the energy system progresses, the heating sector is facing numerous technical challenges that require innovations in the control of network operation and its monitoring, such as

- Integration of renewable sources and waste heat potentials into the grids

- Decentralization of heat generation capacities with volatile feed-in

- Dynamic sector coupling and heating grids as regional energy storage for the power sector

- Adjustment of the temperature level in the networks due to continuously decreasing heat demand due to stricter energy standards for buildings and progressive refurbishment of the building stock

- Steady expansion and extension of grids

Fields of Application of Our District Heating Network Software »AD Net Heat«

District heating suppliers use »AD Net Heat« for:

- Monitoring of the network state

- Optimization of operation (also for decentralized feed-in), e.g. peak load management

- Grid expansion planning and scenario analysis, e.g. expansion of the grid, integration of new sources

- Early fault detection

- Optimal placement of new feed-in locations

- Optimal placement of measurement sensors

Based on the software and a provided network topology, it is possible for us to conduct studies for specific questions, or for suppliers to independently perform network state monitoring via a user-friendly interface.

The graphical user interface of our district heating network software »AD Net Heat« shows the digital twin of a district heating network. © Fraunhofer ITWM

Technical Information About the District Heating Network Software »AD Net Heat«

- »AD Net Heat« is platform-independent and can be used on Windows, Mac or Linux operating systems.

- The operation of the software as well as the visualization of results is realized via a specifically developed user interface. The district heating network software itself consists of a C++ computational core and a Python interface.

- »AD Net Heat« has an automated STANET import for network topologies, also the import of a GIS network model is possible.