The strong increase of electromobility demands the continued development and improvement of the key component of an electric car: the electrical energy storage. The main effort is currently focused on the lithium ion accumulator technology. While these batteries provide high specific power and energy densities, the automobile sector, in particular, demands high standards of safety and durability.

Consequently, a good thermal and electrical battery management system (BMS) is necessary. The more precisely the status of individual cells within a battery pack is known, the better the BMS can ensure the safe and continuous operation of the pack.

Project »Temperature Optimized Battery Component with Instrumented Cells« (TopBat)

One aspect of the collaborative “TopBat” project (“Temperature optimized battery component with instrumented cells”) is concept development and testing of cells that are individually equipped with voltage and temperature sensors. The aim is a sensor integration with the least possible impact on battery performance.

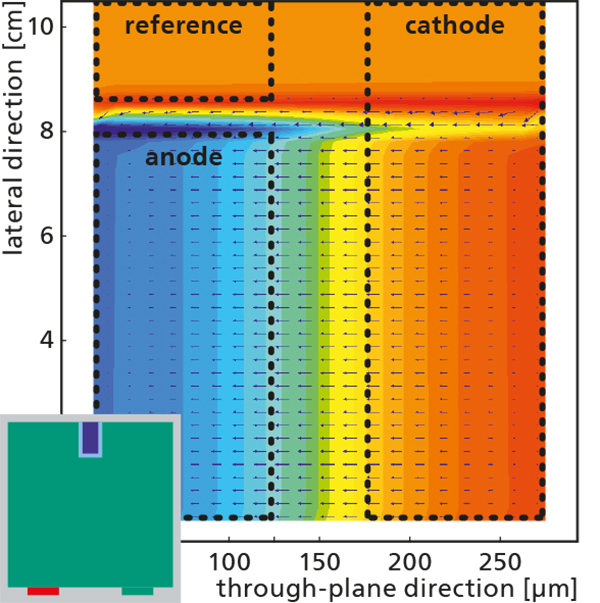

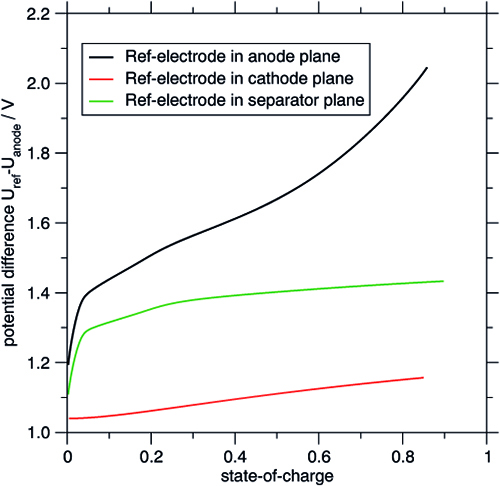

Electrical potential measurements help to evaluate the so called plating risk – a degradation process, in which metallic lithium is deposited that lead to a dangerous short circuit within the cell. In addition to the two battery electrodes (anode and cathode), a reference electrode is introduced in the cell through which no current flows and which serves the sole purpose of measuring the electrical potential. It is the idea of project partner Fraunhofer ISIT to manufacture this reference as porous electrode similar to anode and cathode.

BEST Investigates Geometry of Instrumented Cell

This ensures an easy integration into existing manufacturing processes. The aim of this project is to use computer simulations to study what the geometry of such an enhanced cell must look like (position and size of the reference electrode) in order to provide useful measurement results. Accordingly, the ITWM simulation software BEST (Battery and Electrochemistry Simulation Tool) was expanded and used for the corresponding simulation studies.

BEST is based on a set of partial differential equations that describe the processes within a lithium ion battery. These are solved three dimensionally for a realistic cell. This allows to calculate the reference potentials and to assess in detail how they relate to the plating risk.

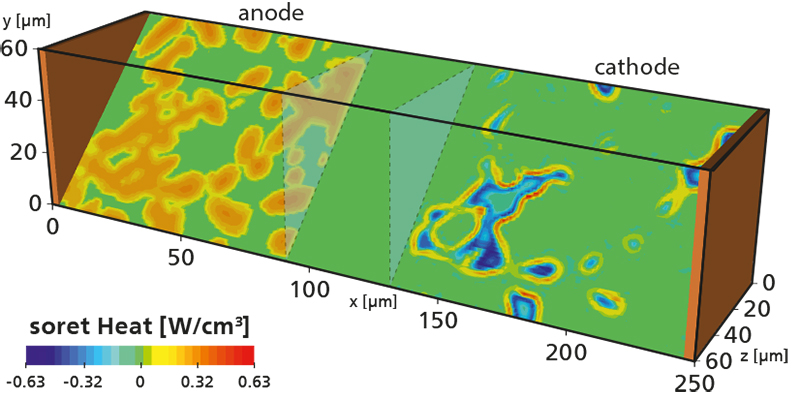

The computation of heat generation and its interaction with the battery performance is another major focus of the project. This is why a thermal-electrochemical battery model has been integrated in BEST, to allow for the determination of the local temperature distribution. This is of great value e.g. for the interpretation of cell-internal temperature measurements.