Systematic studies of deviating measurements in the manufacturing process have yet to provide a way to predict the causal aberrations of components and joints. Although historical trends in the deviations between target and actual dimensions can be detected by statistical process controls, the cause analysis is still missing. While traditional tolerance analysis helps to explain how typical component and joint failure results in measurement deviations, we examine the opposite problem in the Central Innovation Program for SMEs (ZMI). In the project RoMI (Root Cause Analysis of Measurement Issues), we have developed an algorithm and implemented the associated software to analyze potential root causes of aberrations in components or joints.

Root Cause Analysis of Measurement Issues

Project RoMI

The ITWM Component of RoMI

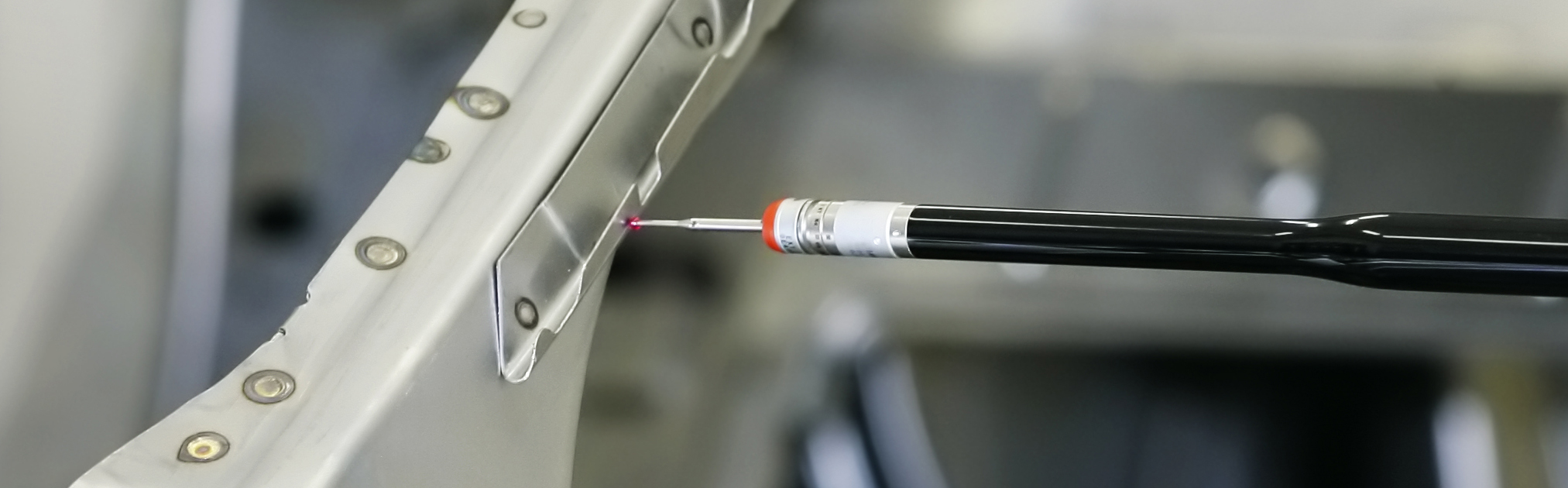

Surface measurements, which have been taken during the production process, allow us to automatically detect defective assemblies and error sources in the joining process. In particular, we can reveal an installation error at a spot that is inaccessible and can no longer be measured after final assembly.

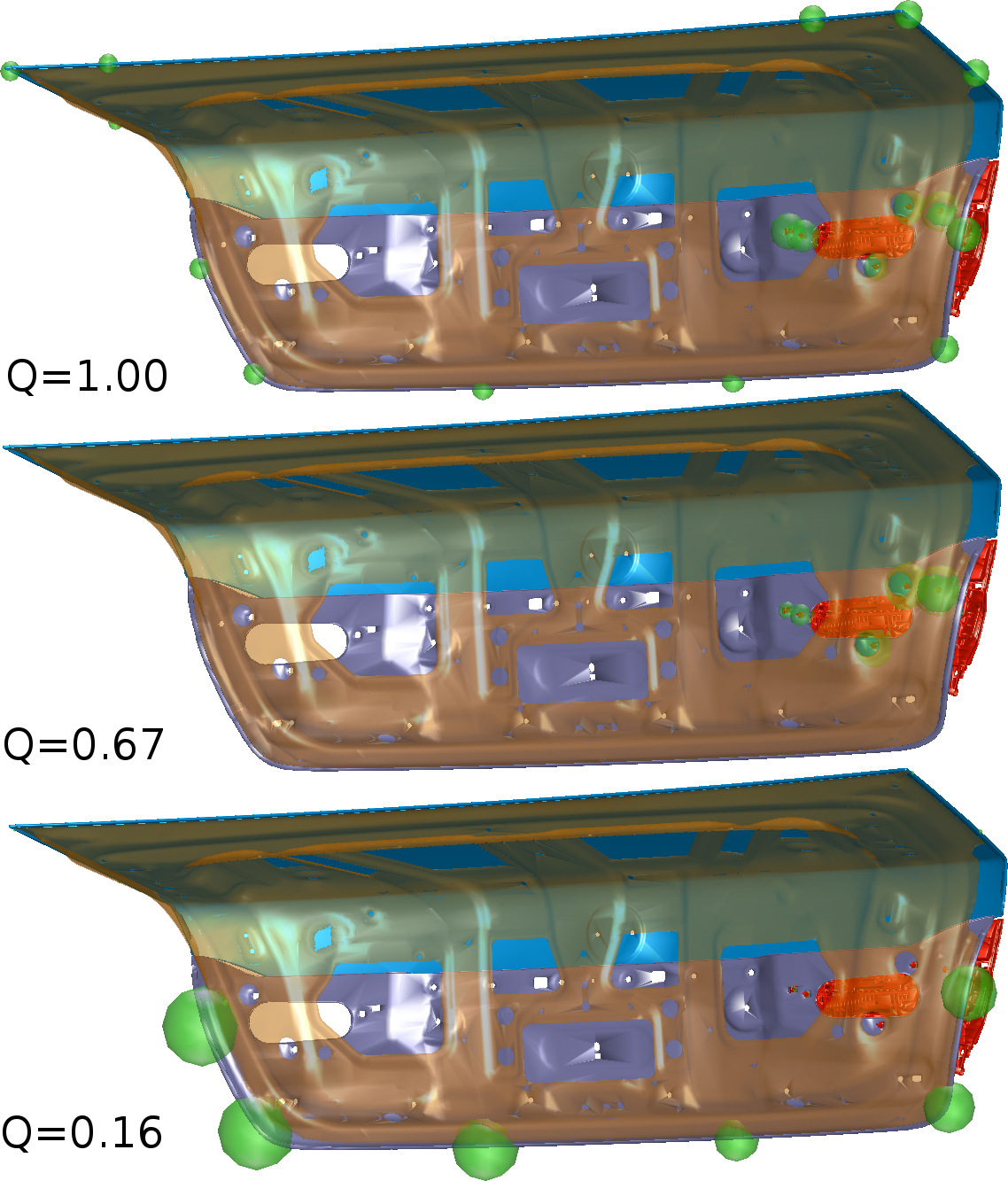

The software is able to simulate different assemblies of the parts. Our algorithm selects the most likely assembly from all the potential combinations of component or joint deviations matching the surface measurements. This selection is achieved by solving a non-linear optimization problem. A special effort is made to ensure that the components are not pervasive. Starting with a set of measurements, the appropriate configuration is found.

This is basically an inverse problem, i.e., from an observed effect on the system, we want to identify the underlying cause. Since there are usually many more failure parameters than measurements, identification usually relies on solving a stochastic optimization problem.

Embedding in eMMA

The new RoMI module is embedded in the eMMA software supplied by project partner Q-DAS (formerly Kronion). Many suppliers from the fields of automobile, shipbuilding, and mechanical engineering have chosen to use this product. This integration ensures the responsible managers are informed in a timely manner before any real problems can emerge from the trends identified.