Foams are ideal thermal or acoustic insulating materials and a good substitute for composite materials. They are therefore not only found in seats of all kinds, but are also used as shock absorbers or for sound and heat insulation.

The properties of the foams significantly determine the functionality of the applications. That is why it is important to be able to take a look inside the foam during production.

New: Automated Material Characterization and Foam Database

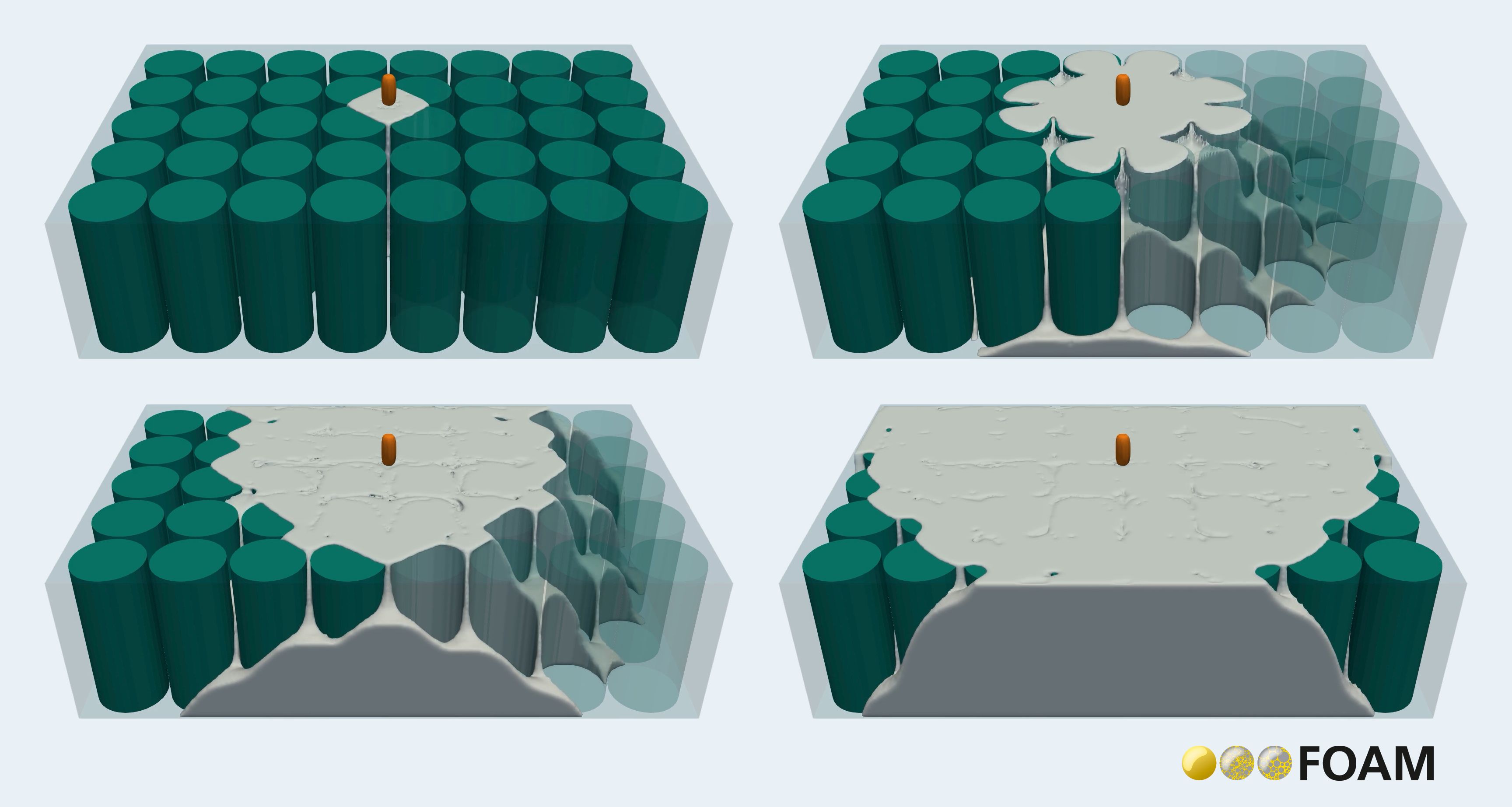

This is made possible by the FOAM software developed at the Fraunhofer ITWM: It simulates the manufacturing process of foams for any components, such as cooling units, seats and much more. The automated process of material parameter identification of foam rheology and expansion chemistry from simple experiments or directly from Foamat® measurements will be presented as a new feature. This allows you to create your own foam databases quickly and directly in FOAM.

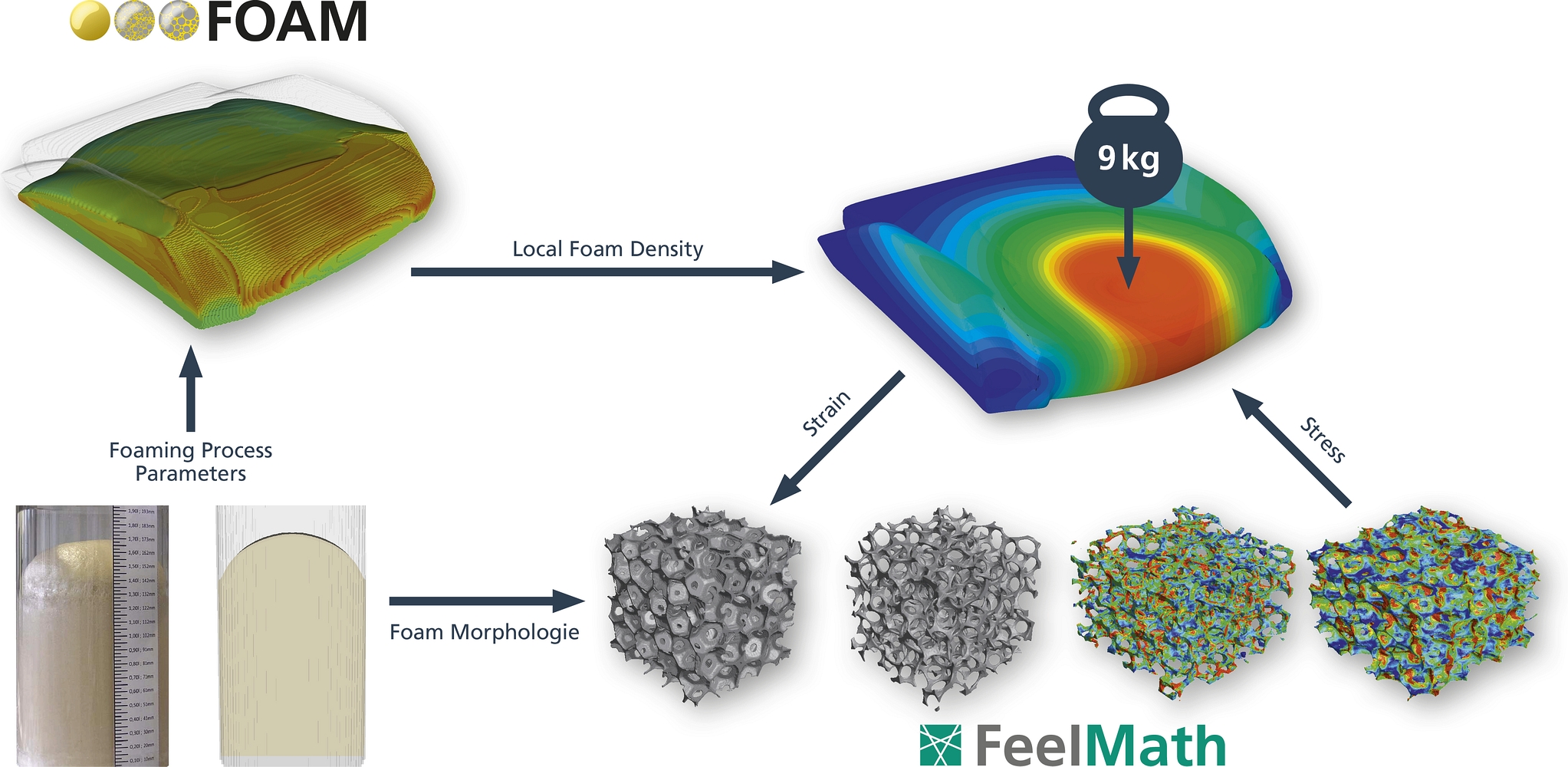

Simulation Chain for Foam Components

The digital twin for foam components begins by simulating the foaming process with FOAM to determine the local density and pore size distribution of the foam component. Based on these results, a foam database is then dynamically created for different densities and pore sizes. This step is based on microstructure simulations of the foam; this is realized with the FeelMath tool, which was also developed at the Fraunhofer ITWM.