The name of the ITWM department says it all: »System Analysis, Prognosis and Control«. The researchers from Kaiserslautern develop AI-based technologies for real-time plant operation and drive technology. The focus is on the integration of artificial intelligence (AI) methods in signal-processing analyses. In this way, they enable the safe monitoring of operating states and the resource-saving predictive maintenance of plants.

A Software for the Artificial Intelligence for Edge Gateways

Industrial plants are monitored with a range of sensors for control and monitoring, and their data is often stored in cloud systems for analysis. However, information security concerns or the volumes of data generated at high sampling rates require smarter solutions at the interface between the control cabinet and the intranet. The researchers at Fraunhofer ITWM are equipping edge devices in the control cabinet with software that collects information relevant to the process from the signals of all sensors and enables, for example, an artificial intelligence to generate targeted warnings or suggestions. The software is independent of the measuring system so that maintenance applications can be implemented precisely for each machine or production line.

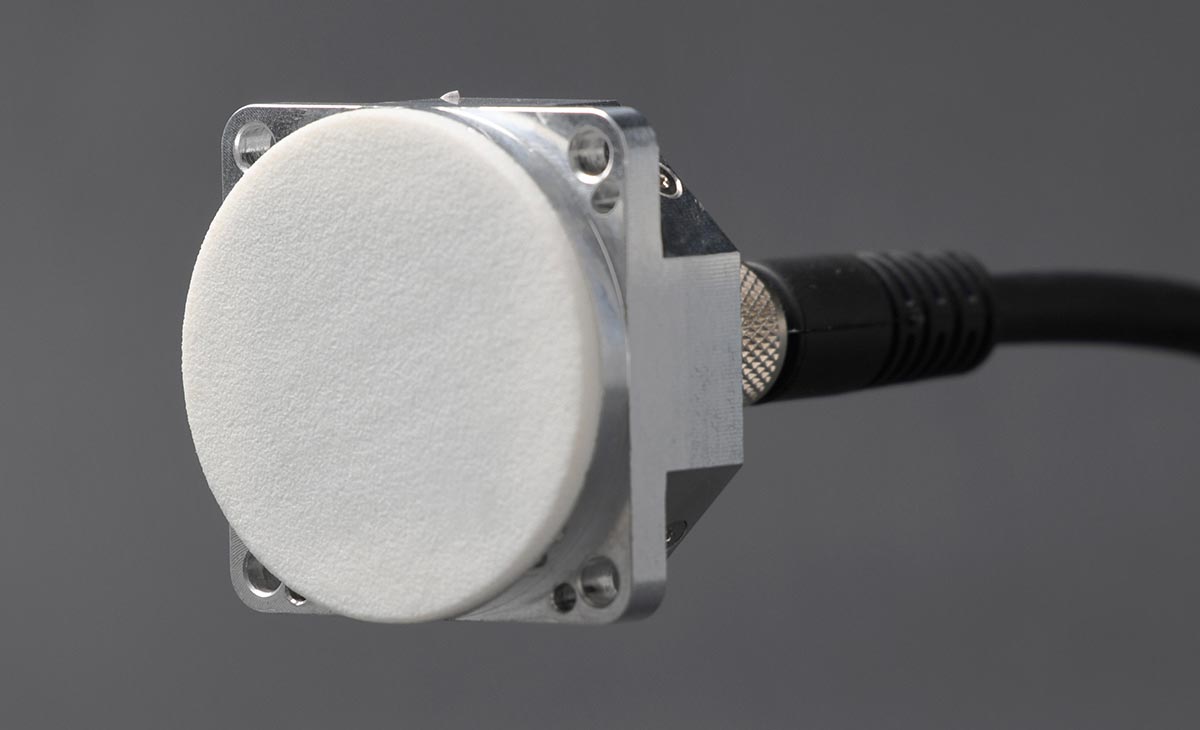

A wide variety of sensors can be used, for example acceleration, distance and current sensors or even industrial cameras. One of the sensors used by the Fraunhofer ITWM, which has many years of experience in condition monitoring systems, is a magnetostrictive sensor for the contactless detection of torques.