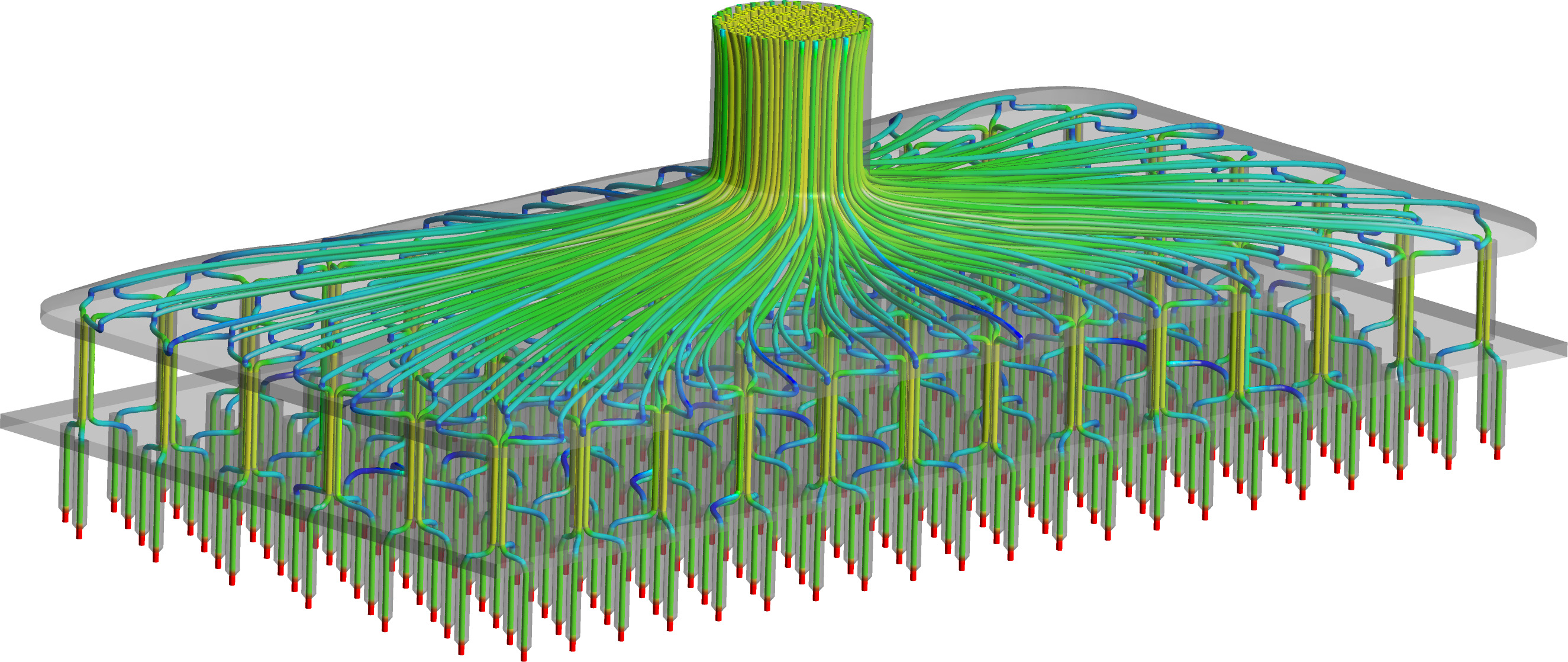

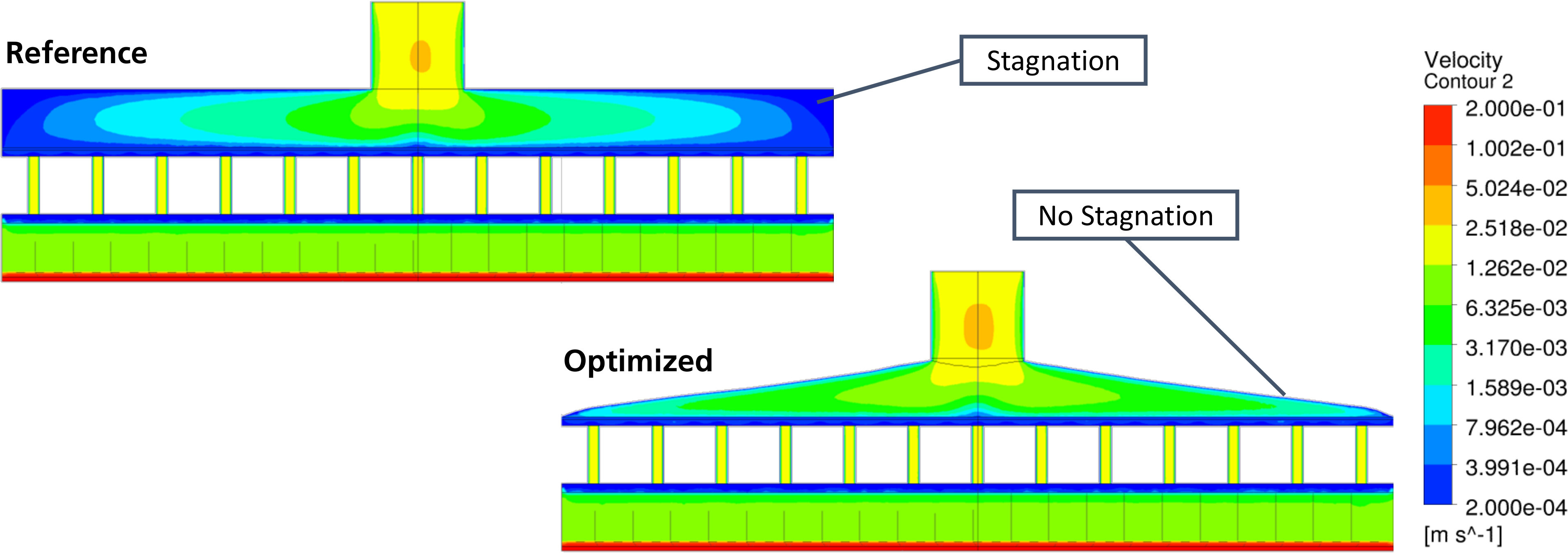

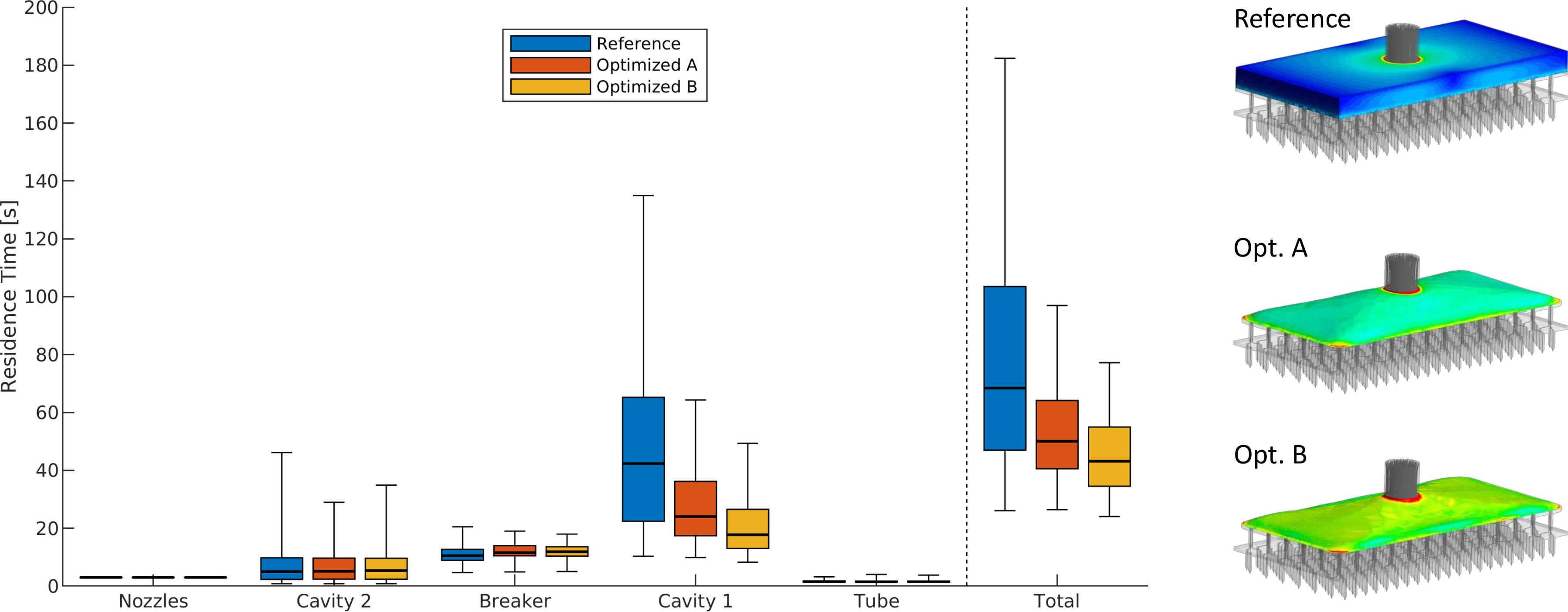

Our software solutions simulate spin packs as a digital twin to understand the flow behavior inside and to optimize the design.

Spin packs are used in the production of synthetic fibers and nonwovens. The spin pack itself is a metal block and consists of cavities and fine channels inside, through which polymer melt – i.e. molten plastic – flows. This melt is fed into the spin pack through a tube. In a first cavity, the melt is distributed over the entire width of the spin pack. It passes through several layers of filters held by a support before being spun into fibers by fine capillaries in the spinneret plate.. This produces fibers that are either wound into a yarn or laid down to form a nonwoven fabric.